MIL-PRF-1/1383D

TABLE I. Testing and inspection - Continued.

1/

The filament voltage is 60 Hz ac or dc. The life of the tube can be conserved by operating the filament at the lowest power

which will enable the tube to provide the desired power output. The filament voltage shall be measured at the respective

water connections on the tube side of the threads. This procedure is essential in order to accurately measure the filament

voltage. The filament starting current shall never exceed 1,200 amperes, even momentarily. It is recommended that filament

voltage be monitored. The filament voltage shall never exceed the value indicated. In applications where it is feasible to

monitor filament voltage, it is permissible to monitor filament current. Under such conditions, the tube shall be operated with

the filament current not exceeding 1,050 amperes.

2/

Tie each element not under test to ground. Two tubes per month shall be tested. Failure of one or more tubes shall require

100 percent testing. Testing of two tubes per month may be resumed after testing of 10-consecutive tubes without failure.

Any tube having one or more inter-electrode capacitances greater than 100 pF shall be measured for all of its capacitances

on suitable capacitance or impedance bridges operating at 1,000 Hz.

3/

The difference between the filament currents of the sections of any tube shall not exceed 30 amperes.

4/

On time (tp) is defined as the sum of the duration of all the individual pulses which occur during any 37,300 microsecond

interval.

5/

Peak rectified grid 1 current.

6/

After the application of filament voltage, a minimum of 30 seconds heating time is required before other electrode voltage can

be applied.

7/

Cooling requirements. Water cooling of the filament sections, dc cathode, grid 1, grid 2, and the anode is required. The

waterflow shall start before application of any voltages, in order to purge the system of bubbles, and shall continue for at least

10 seconds after removal of all voltages. In order to purge the system of bubbles, and shall continue for at least 10 seconds

after removal of all voltages. Interlocking of waterflow through each of the cooled elements with all power supplies is

recommended to prevent tube damage in case of failure of adequate waterflow. Waterflow shall be as shown in table IA.

8/

The waterflow to the anode cooling connection shall be 12 gpm. The waterflow to the filament sections, dc cathode, grid 1,

and grid 2 cooling connections, shall be 0.8 gpm. Waterflow shall start before the application of any voltages, and shall

continue for at least 10 seconds after removal of all voltages. The outlet water temperature shall not exceed 70°C.

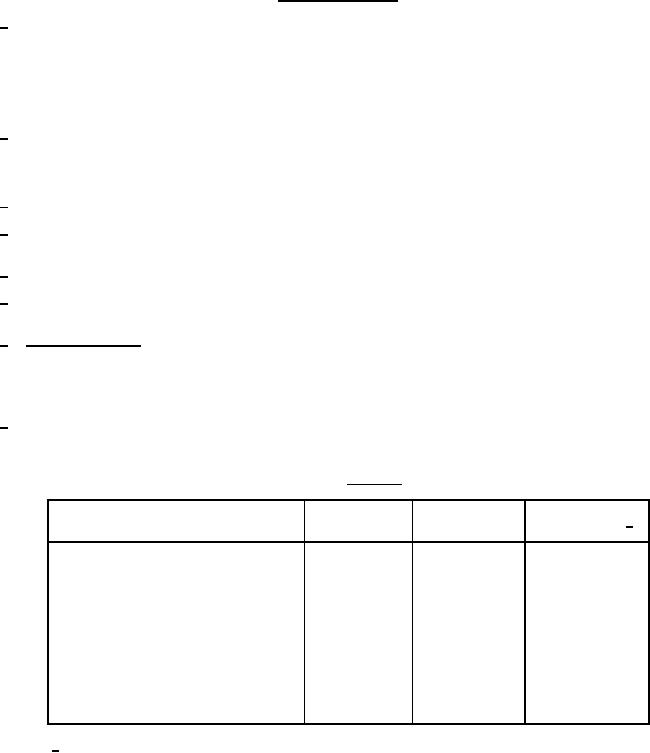

TABLE IA. Waterflow.

Maximum pressure

Absolute

Typical

differential (psi) 1/

minimum gpm

gpm

for typical flow

To filament section No. 1 connection

0.8

1.2

17

To filament section No. 2 connection

0.8

1.2

17

To dc-cathode connection

0.8

1.2

11

To grid 1 connection

0.8

1.2

9

To grid 2 connection

0.8

1.2

17

To anode connection

For average anode dissipation to 12 kw

12

14

18

For average anode dissipation to 20 kw

18

20

55

150 max °C

Ceramic bushing temperature

---

---

70 max °C

Outlet water temperature (any outlet)

---

---

1/ Measured directly across the cooled element.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business