MIL-PRF-1/999C

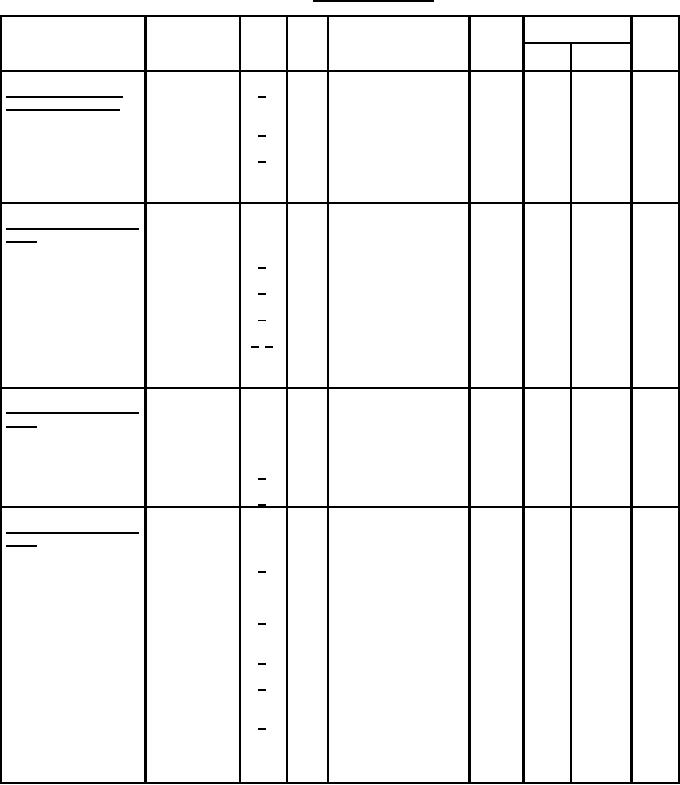

TABLE I. Testing and inspection.

Inspection

Method

Notes

Test

Conditions

Symbol

Unit

Limits

MIL-STD-1311

Min

Max

Preproduction sample

1/

approval inspection

Loaded Q

4461

2/

---

F0 = F1

QL

---

8.5

---

High-level VSWR

4474

2/

2

VSWR

---

1.15

---

Degradation due to

4021

---

---

---

---

---

---

vibration

Conformance inspection,

part 1

Tuning susceptance

4482

2/

---

F0 = F2; g = 0.05

b

-0.06

+0.06

---

Firing time

4486

3/

1

t

---

10

sec

Arc loss

4488

3/

1

La

---

0.8

dB

Electrical symmetry

---

2/ 4/

---

F0 = F2; g = 0.05

---

---

0.06

cm

Temperature cycling

1027

---

---

---

---

---

---

(nonoperating)

Conformance inspection,

part 2

Dielectric material strain

4101

---

---

---

---

---

---

Normalized conductance

4484

2/

---

F0 = F2

g

---

0.06

---

μs

Recovery time

4471

2/

3

t

---

10

Conformance inspection,

part 3

Life test

---

6/

3

Group D

t

500

---

hrs

Life-test end points:

---

Tuning susceptance

4482

2/

---

Method A; F0 = F2;

b

-0.08

+0.08

---

g = 0.05

Arc loss

4488

3/

1

La

---

1.0

dB

Normalized

4484

2/

---

F0 = F2

g

---

0.1

---

conductance

μs

Recovery time

4471

2/

3

t

---

15

Temperature cycling

1027

---

---

Group D;

---

---

---

---

life test

10 cycles (min)

See footnotes at top of next page.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business