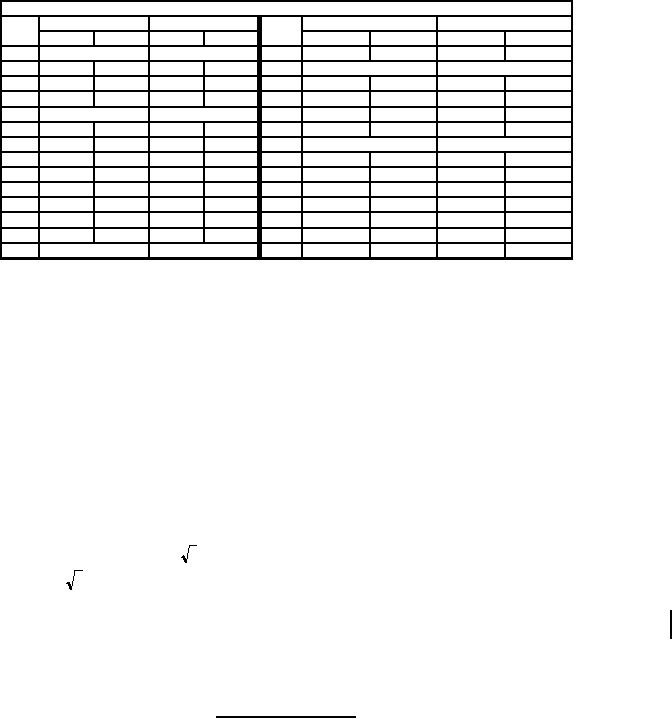

MIL-PRF-1/1705C

Dimensions

Ltr

Inches

Millimeters

Ltr

Inches

Millimeters

Min

Max

Min

Max

Min

Max

Min

Max

A

.125-27 NPT

3.18-27 NPT

Q

3.359 dia

3.390 dia

85.32 dia

86.11 dia

B

2.495

2.505

63.37

63.63

R

.125-27 NPT

3.18-27 NPT

C

1.245

1.255

31.62

31.88

S

1.359

1.391

34.52

35.33

D

3.167

3.177

80.44

80.69

T

.134

.142

3.40

3.61

E

.250-20 x 1.0 LG

6.25-20 x 10. LG

U

---

.005

---

0.13

F

2.609

2.640

66.27

67.06

V

.127

.135

3.23

3.43

G

1.495

1.505

37.97

38.23

W

.030 Rad Nom

0.76 Rad Nom

H

2.995

3.005

76.07

76.33

X

---

.005 typ

---

0.13 typ

J

4.984

5.016

126.59

127.41

Y

3.167

3.177

80.44

80.70

K

.484

.516

12.29

13.11

Z

.182

.192

4.62

4.88

L

3.484

3.516

88.49

89.31

AA

.111

.113

2.82

2.87

M

3.234

3.265

82.14

82.93

AB

1°30'

2°30'

1°30'

2°30'

N

.484

.516

12.29

13.11

AC

1°30'

2°30'

1°30'

2°30'

P

.062 Nom

1.57 Nom

AD

.088

.098

2.23

2.49

NOTES:

1. Material (base and cover) corrosion resistance in accordance with ASTM-A484/A484M and ASTM-A582/A582M.

2. Material (gasket) LS-53 fluorosilicone rubber 45 ± 5 duro. shore A.

3. Dimension are in inches, with millimeter equivalents provided.

4. Diameters shall be concentric within .005 T.I.R.

5. Remove all burrs, break sharp edges.

125

6. Surfaces of base and cover shall be

finish, unless as noted.

32

finish shall be free of tool marks and scratches.

7. Surfaces with

8. Gasket surfaces indicated shall be free of any defects, blemishes, or surface irregularities.

9. Passivate in accordance with MIL-F-14072 (E300) (base and cover).

10. This fixture to be used for the pressurization test.

FIGURE 3. Magnetron input test fixture - Continued.

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business