MIL-PRF-1/160N

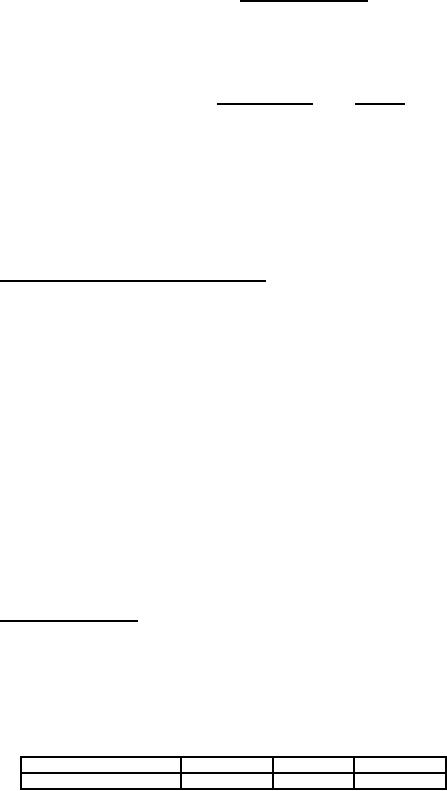

TABLE I. Testing and Inspection. - Continued.

NOTES: - Continued.

2. Maximum life may be obtained by adjusting the heater voltage in accordance with the application. A table of heater

voltage verse frequency is presented as a guide.

Frequency (MHz)

Ef (V ac)

Up to 300

6.00

301 to 400

5.75

401 to 500

5.50

3. In all cases of electrical tests involving application of heater voltage, the socket on Drawing 246-JAN (see note 13) shall

be used. An incoming airflow of 6.0 cfm maximum to the grid end of the socket is permitted.

4. An infinite baffle system as shown on figure 2, or equal, with an airflow of 5.6 cfm at sea level shall be used. The static

pressure drop is measured across the tube and socket.

5. The forced-cooling test shall be made as follows:

At an ambient temperature of 25 °C, both the base and the anode shall be cooled by applying an airflow of 5.6 cfm

maximum, at sea level from a single source using the infinite baffle system as shown on figure 2, or equal.

At the specified test conditions, the anode core temperature, the anode seal temperature, and the base seal temperature

shall not exceed the specified limits.

All temperatures shall be measured by means of thermocouples located as follows:

Anode core: This thermocouple shall be embedded in the top of the cooler, with the anode dome removed, if necessary,

by means of drilling a small hole, shallow enough so that the tube vacuum shall not be lost, placing the welded

thermocouple junction therein, and then bending the edges of the hole in order to hold the thermocouple firmly in place.

Anode seal: This thermocouple shall be attached, using any appropriate material, to the surface of the metal immediately

above metal-to-dielectric seal.

Base seal: This thermocouple shall be attached, using any appropriate material, to the surface of the metal immediately

adjacent to the base dielectric material and at the immediate periphery of the dielectric material.

In all cases, good electrical continuity between the thermocouple and the metal area in close proximity must be

demonstrated before the cooling test can be performed.

6. This is a destructive test. Operate the tube in an upright position. Preheat the tube at specified test conditions for 1

minute. Remove airflow for 100 seconds. Restore airflow and after 1 minute perform the total grid current test. Any tube

which evidences a short or open circuit during this test will be considered a failure.

7. The maximum value of the voltage applied to the anode and grids shall not exceed 900 volts. The pulse duration

measured at 5 percent of the maximum value shall be not less than 3 microseconds (µs). At 50 percent amplitude, the

duration shall be less than 2 µs. The applied voltage shall have a maximum repetition rate such that the duty cycle,

based on the pulse length measured at 50 percent amplitude, shall not exceed 0.0002 (0.02 percent). An alternate

pulsing emission test may be used with the following conditions and limits:

Conditions

Parameter

Minimum

Maximum

is = 30 a , eb = ec1 = ec2

etd

---

850 v

For life-test end points, is = 21 a.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business