MIL-PRF-1/422J

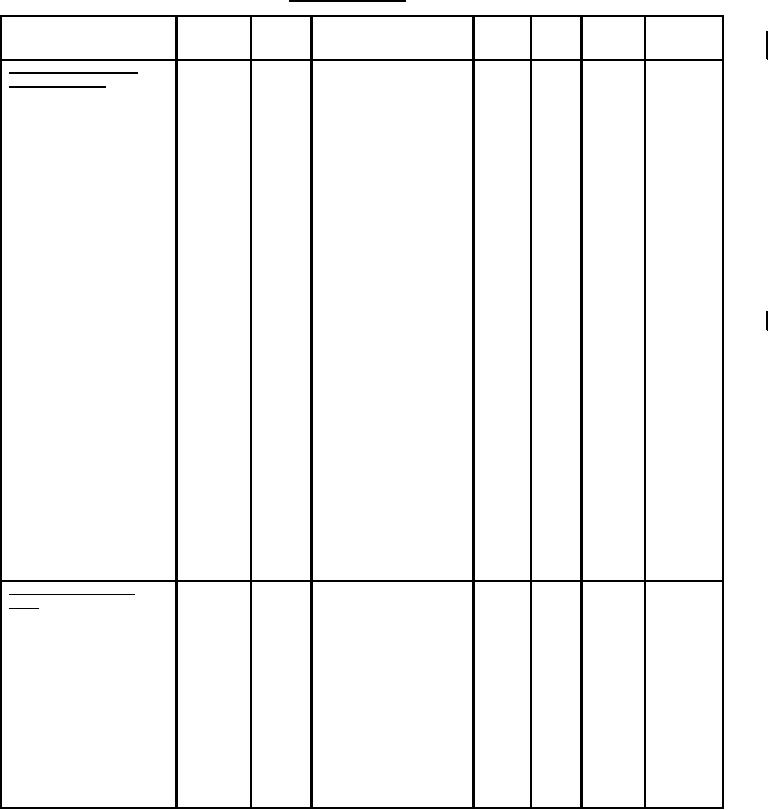

TABLE I. Testing and inspection -Continued.

Inspection

Method

Notes

Conditions

Symbol

Limits

Limits

Unit

MIL-STD-

Min

Max

1311

Conformance inspection,

part 2 - Continued

---

---

---

---

Base key, collar index pin

5101

Side terminal and base

alignment

---

---

---

---

---

5101

Neck and base alignment

(electrostatic types)

Ib3 = 25 µA dc

mm

0.65

---

W idth

---

5226

Line width "A" (electrostatic

deflection)

Ib3 = 25 µA dc

mm

0.80

---

W idth

7

5226

Line width "B" (electrostatic

deflection)

Focusing voltage at Ib = 25 µA

V dc

650

450

Eb1

---

5246

direct current

V dc/in.

80

68

DF

9

5248

Deflection factor

1D2

V dc/in.

37

27

DF

10

5248

Deflection factor

3D4

µA dc

15

---

Ihk

---

5251

Heater-cathode leakage

current

92

88

---

---

5101

Degrees

Angle between traces

---

---

---

12

---

---

Trace alignment

0 failures

---

---

---

1111

---

Base pin solder depth

Sample size shall be

1 percent of lot (lot = 1

month's production)

---

---

---

15

1101

---

Secureness of base, cap

or insert

---

---

---

---

1105

---

Permanence of marking

For qualifications only.

Conformance inspection,

part 3

---

---

---

---

Group C;

14

---

Life test

t = 500 hours;

Ib3 = 25 µA dc

---

Life-test end points:

ĆEc1

Ib3 = 40 µA dc

V dc

55

---

---

5223

Modulation

Ib3 = 18 µA dc

mm

0.65

---

---

5226

Line width "A"

W idth

Ib3 = 18 µA dc

mm

0.80

---

---

5226

Line width "B"

W idth

---

---

---

5

1141

Pressure (implosion)

---

mm

1.0

---

5

5111

Vibration

W idth

For qualification only.

See notes at end of table I.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business