MIL-PRF-1/22J

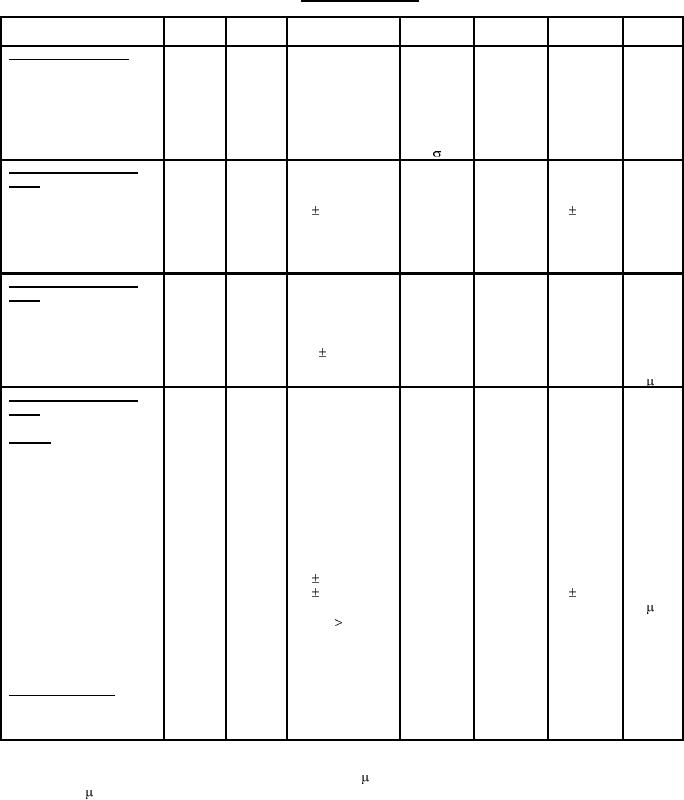

Table I. Testing and Inspection.

Inspection

Method

Notes

Conditions

Symbol

Limits

Limits

Unit

Min

Max

Qualification inspection

Degradation due to

---

---

---

4021

-

---

vibration

---

6.5

---

4461

-

Loaded Q (ATR tubes)

QL

---

1.10

---

High-level VSWR

4474

-

Test condition 2

Conformance inspection,

part 1

Tuning susceptance

4482

-

b = B/Yo

---

---

Fo

0.1% MHz

0.06

Firing time

4486

3

t

---

sec

10

Arc loss

4488

3

La

---

dB

0.8

Conformance inspection,

part 2

Dielectric material strain

4101

-

---

---

---

---

Normalized conductance

4484

-

g = G/Yo

---

0.1

---

Fo

0.1% MHz

Recovery time

4471

-

t

---

10

Test condition 1

s

Conformance inspection,

part 3

Life test

---

-

Group D;

test condition 1

Type 1B35A

-

---

500

---

Hrs

Type 1B37A

-

---

500

---

Hrs

Type 6162

-

---

500

---

Hrs

Type 5864

-

---

1,000

---

Hrs

---

Life-test end points:

4488

Arc loss

3

1.0

---

La

dB

4484

Normalized conductance

-

0.1

---

g = G/Yo

---

Fo 0.1% MHz

4482

Tuning susceptance

-

---

b = B/Yo

---

0.06

Fo 0.1% MHz

4471

Recovery time

-

---

t

20

s

Test condition 1;

VSWR 10 dB

1027

Temperature cycling

-

---

---

---

---

(nonoperating)

Periodic-check tests

Temperature cycling

1027

3

---

---

---

---

Group D;

life-test end point

10 cycles (min)

NOTES:

1. For 500 hours life, the duty cycle is 0.001 at pulse width of 1.0 s. Operation at greater

than 1.0 s pulse width at 250 kw is permissible but may result in decreased life.

2.

For electrical tests, the tubes shall be mounted as shown on figure 2. A suitable gasket

shall be placed between the tube and the tube seat.

3.

This test shall be performed at least 168 hours after pumping, and at least 24 hours after

any previous discharge.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business