MIL-PRF-1/1733A(NAVY)

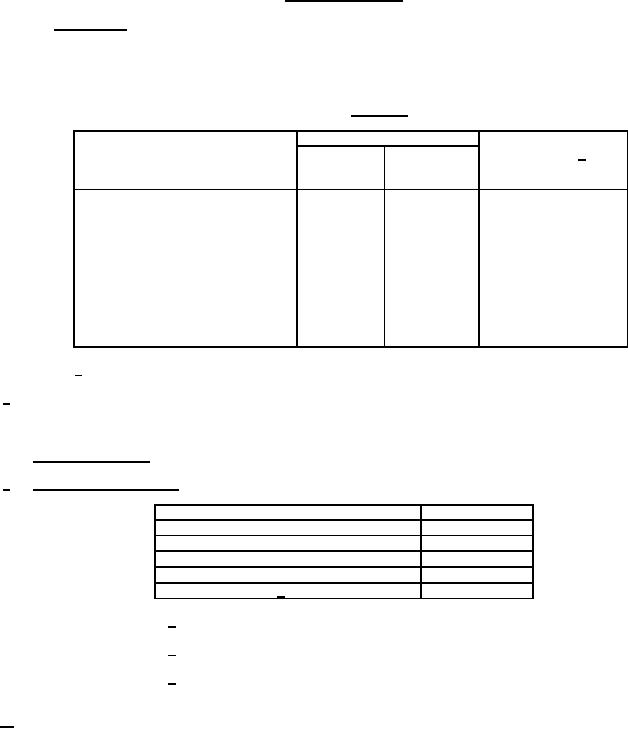

TABLE I. Testing and inspection - Continued.

b.

Liquid cooling. Liquid cooling of the filament block, dc cathode block, grid(1) block, grid(2) block, and anode, is required.

When the environmental temperature is above 0GC, the coolant may be water. The liquid flow shall start before application of

any voltages and preferably shall continue for several seconds after removal of all voltages. Interlocking of the liquid flow

through each of the cooled elements with all power supplies is recommended to prevent tube damage in case of failure of

adequate liquid flow. Liquid flow shall be as shown in table IA.

TABLE IA. Liquid flow.

Waterflow

Maximum pressure

Coolant course

Absolute

differential 1/

for typical flow

minimum

Typical

(psi)

(gpm)

(gpm)

With water:

Through filament block - - - - - - - - - -

0.5

0.8

8

Through dc cathode block- - - - - - - -

0.5

0.8

8

Through grid(1) block - - - - - - - - - - -

0.5

0.8

6

Through grid(2) block - - - - - - - - - - -

0.5

0.8

8

Through anode in direction shown

on figure 1:

For anode dissipation up to

11 kW (average) - - - - - - - - - -

8

10

10

For anode dissipation of

14 kW (average- - - - - - - - - - -

10

12

15

1/ Directly across cooled element.

8/

The water flow to the anode cooling connection shall be 8 +1, -0 gpm. The minimum water flow to the filament, filament-cathode,

grid(1) cooling connections, shall be 0.5 gpm. Water flow shall start before the application of any voltages, and shall be continued

for at least 6 seconds after removal of all voltages. The outlet water temperature shall not exceed +70GC.

Emergency conditions: Simultaneous interruption of cooling pump and tube electrode power is permissible.

9/

Environmental requirements.

External gas pressure (absolute) 1/

60 psi (max) 2/

Gage pressure at any inlet

100 psi (max)

Metal-surface temperature

100GC max

Ceramic bushing temperature

150GC max

Outlet liquid temperature (any outlet) for water

70GC max

Storage temperature 3/

-65GC max

1/ Absolute pressure is the sum of the atmospheric pressure

and gage pressure.

2/ This pressure is related to the output cavity pressurization as

required to prevent corona or external flashover.

3/ The tube coolant ducts shall be free of liquid before storage or

shipment of the tube to prevent damage from freezing.

10/

High-speed electronic protective devices shall be used to prevent energy from the anode power supply, from the grid(1) power

supply, and from the grid(2) power supply from permanently damaging the tube and its circuitry in the event of abnormal operation.

A suitable high-speed electronic protective device shall be capable of deactivating the various pulse sources supplying the tube

during the inter-pulse interval following the occurrence of a fault in any single pulse, and shall be capable of meeting the

requirements of the aluminum foil simulated fault tests. Thus, all pulses subsequent to a "fault" pulse shall not be applied until the

device is reset. (A fault is a condition in which the peak pulse currents rise 20 percent or more above the normal peak current

level.) Additional protection against damage from an anode-to-grid(2) fault shall be provided to prevent the grid(2) voltage from

rising to a value in excess of 3,000 volts during the fault pulse. Minimum reset time shall be 1 second.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business