MIL-PRF-1/1635C

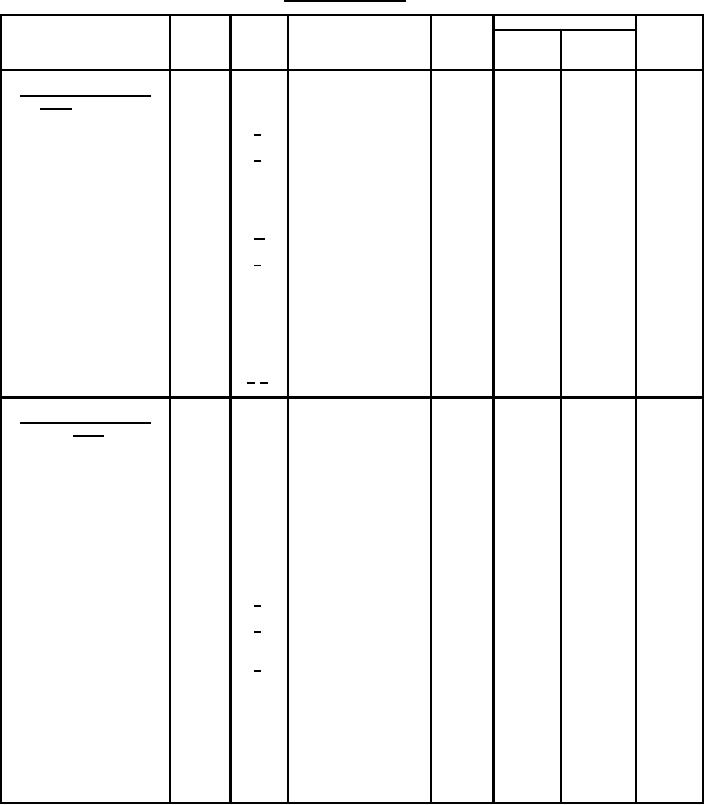

TABLE I. Testing and inspection - Continued.

Limits

Notes

Conditions

Symbol

Min

Max

Unit

Inspection

Method

MIL-STD-

1311

Conformance inspection

part 1 - Continued

---

---

---

---

Spot examination

---

7/

Focused trace;

---

Minimum useful scan

---

6/

beam current = 2.5 A dc

Inches

9

---

---

---

1D2

Inches

9

---

---

---

3D4

Screen charging

---

8/

---

---

---

---

Deflection defocusing

---

9/

---

---

1:3

Ratio

Pattern distortion

5103

---

---

---

2

%

1101

---

---

---

---

---

Secureness of base, cap,

or insert

Base pin solder depth

1111

---

---

---

---

---

Permanence of marking

1105

3/ 4/

---

---

---

---

Conformance inspection

part 2

Degrees

---

1.5

---

5101

---

Neck and base alignment

(electrostatic types)

Heater current

1301

---

If

540

660

mA

5101

---

+1D2, index pin

---

---

---

---

Base alignment

(electrostatic types)

A dc

5201

---

Ib1

-15

+10

Electrode current

(anode No. 1)

Screens

5221

6/

---

---

---

---

Beam current = 2.5 A dc

5226

6/

Line width A

---

---

0.30

mm

(electrostatic deflection)

Beam current = 2.5 A dc

5226

6/

Line width B

---

---

0.42

mm

(electrostatic deflection)

Anode No. 1 leakage current

5251

---

---

---

---

---

Anode No. 2 leakage current

5251

---

---

---

---

---

Deflection factor

5248

---

1D2

---

155

189

V dc/inch

Deflection factor

5248

---

3D4

---

151

185

V dc/inch

See footnotes at end of table.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business