MIL-PRF-1/1605B

NOTES:

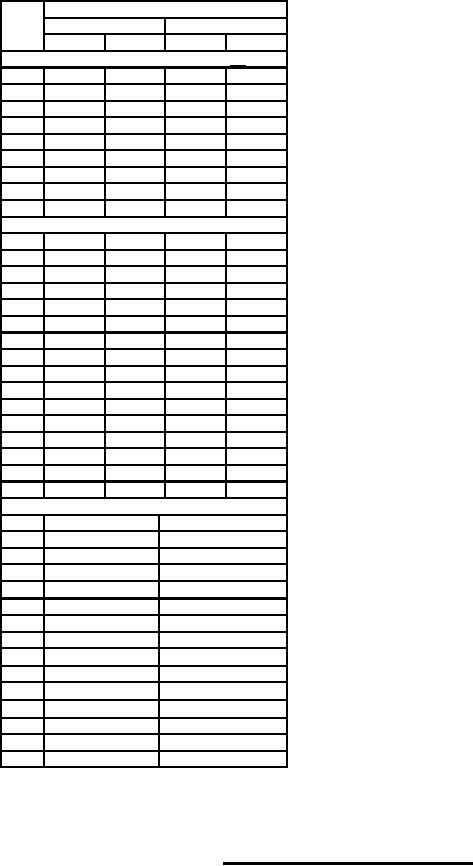

Dimensions

1. Reference plane "A" is defined as a plane passing along

Ltr

Inches

Millimeters

the face of the mounting surface as shown.

Min

Max

Min

Max

2. Reference plane "B" is defined as a plane perpendicular

Conformance inspection, part 1 25/

to plane "A" passing through the axis of diameter "ZZ" at

A

4.867

5.241 123.62 133.12

plane "A" and midway between the axes of holes "YY"

B

18.615 18.950 472.82 481.33

at plane "A".

C

---

4.455

---

113.16

3. Reference plane "C" is defined as a plane mutually

N

1.200

1.240

30.48

31.50

perpendicular to planes "A" and "B" passing through the

P

.0595

.0655

1.51

1.66

axis of diameter "ZZ" at reference plane "A".

S

4.960

5.040 125.98 128.02

4. This flange shall mate with a modified M3922/61-002.

V

.500

.520

12.70

13.21

5. This part shall mate with a type "N" plug.

6. These dimensions apply to the axes of diameter "RR" and

Y

.187

---

4.75

---

"PP".

AG

.308

.316

7.82

8.03

7. Terminal for ground adapter.

Conformance inspection, part 2

8. This dimension refers to the axis of diameter "XX".

D

3.632

3.882

92.25

98.60

9. rf input (type "N").

G

.312

---

7.92

---

10. rf output

H

.367

.383

9.32

9.73

11. This section of the tube may be composed of numerous

K

.306

.312

7.77

7.92

laminations, each containing a "V" notch.

L

.855

.895

21.72

22.73

12. Pitch diameter shall accept a class 2 "GO" gauge only.

R

.950

1.050

24.13

26.67

13. Minor diameter shall be not greater than .166 inch

U

.375

---

9.52

---

(4.22 mm).

W

---

3.375

---

85.73

14. This part shall be equivalent to AN-D10050-6.

X

.370

.380

9.40

9.65

15. Getter bushing.

Z

---

3.125

---

79.38

16. Cathode temperature measurement point.

AB

.084

.104

2.13

2.64

17. This part shall be equivalent to AN-D10050-8.

18. For termination.

AD

5.031

5.051

127.79 128.30

19. This part shall mate with an UG-45/U coupling flange.

AE

5.285

5.315

134.24 135.00

20. The axis of this diameter shall lie on reference plane "B"

AJ

1.006

1.050

25.55

26.67

within .020 inch (0.51 mm).

AK

2.342

2.372

59.49

60.25

21. These diameters and mounting holes "W W " shall

AI

.780

---

19.81

---

simultaneously accept a gauge 22.500 inch (571.50 mm)

Nominal dimensions

long with a 2.652 inch (67.36 mm) I. D. with pins as

E

17.125

435.00

shown on "MOUNTING HOLE GAUGE."

F

.235

5.97

22. This surface shall be perpendicular to reference "A" within

J

.850

21.60

.020 inch (0.51 mm).

M

1.050

26.70

23. A centerline created by these pins shall be parallel to

Q

45°

45°

reference plane "A" within .040 inch (1.02 mm) and pass

T

1.000

25.40

through axis of diameter "XX" within .004 inch (0.102 mm).

AA

.063

1.60

24. This surface shall be parallel to a centerline passing

AC

1.750

44.50

through pins "SS" within .025 inch (0.64 mm).

25. This specification uses accept on zero defect sampling

AF

20°

20°

plan in accordance with MIL-PRF-1, table III.

AH

.190-32

4.83-32

AM

22°30'

22°30'

AN

10°

10°

AP

3.410 DIA

86.61 DIA

AQ

.255 DIA

6.48 DIA

AR

.500

12.70

FIGURE 1. Outline drawing of electron tube type 8128 - Continued.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business