MIL-PRF-1/1400D

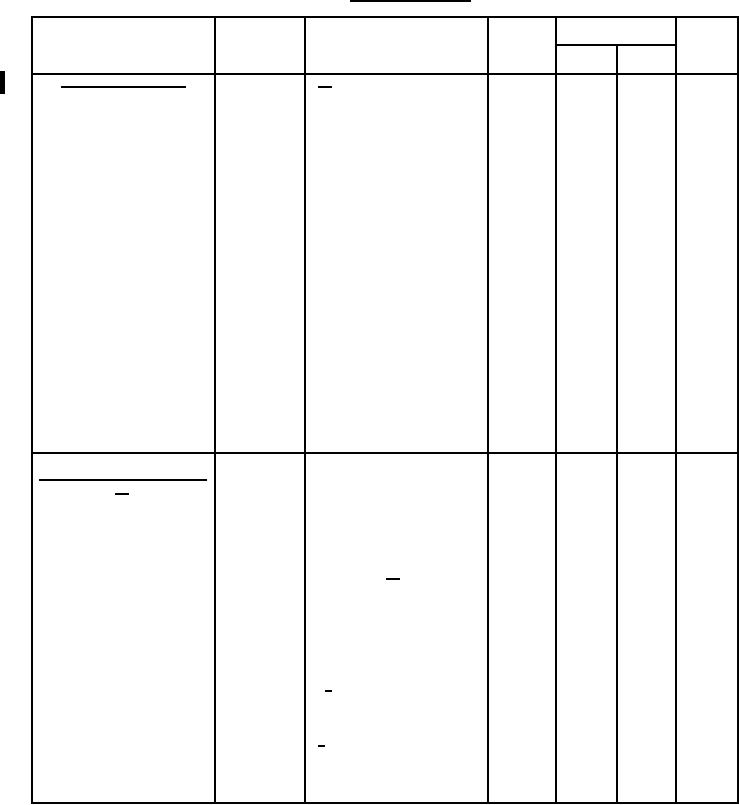

TABLE I. Testing and inspection.

Inspection

Method

Conditions

Symbol

Limits

Unit

MIL-STD-1311

Min

Max

Qualification Inspection

14/

Alignment, neck and bulb

5101

---

---

---

4.375

inch

Cathode illumination

5216

---

---

---

---

---

Deflection factor uniformity

5248

1D2

---

---

2

%

3D4

---

---

2.5

%

-5

Interaction factor

5250

---

---

inch/V dc

6x10

°C

Low temperature operation

1026

---

---

-65

---

°C

High temperature operation

1026

---

---

+85

Direct interelectrode

1331

Cathode to all

C

---

7.0

pF

capacitances

Grid 1 to all

C

---

7.0

pF

D1 to D2

C

---

5.0

pF

D3 to D4

C

---

5.0

pF

D1 to all

C

---

9.9

pF

D2 to all

C

---

9.9

pF

D3 to all

C

---

8.6

pF

D4 to all

C

---

8.6

pF

Pressure

1141

---

---

---

---

---

Vibration

5111

---

Width

---

2

mm

Conformance inspection, part 1

13/

Ib3 = 5 µA dc

µA dc

5201

IK

---

500

Cathode current

Voltage breakdown

5201

---

---

---

---

---

Ib3 = 5 µA dc 12/

Gas

5206

---

---

---

---

±10

Alignment base

5101

+1D2, base key

---

---

degrees

±5

Alignment side terminal

5101

+1D2

---

---

degrees

Alignment side terminal and base

5101

Base key

---

---

---

---

Angle between traces

5101

---

---

1

degrees

4/

---

89

91

degrees

Guns A and B

Gun C

---

88

92

degrees

Trace alignment

5010

5/

---

---

---

---

Stray emission

5216

---

---

---

---

Ec2 = 6,000 V dc;

Eb2 = 6,000 V dc;

Eb3 = 15,000 V dc

See footnotes at end of table.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business