MIL-PRF-1/1339F

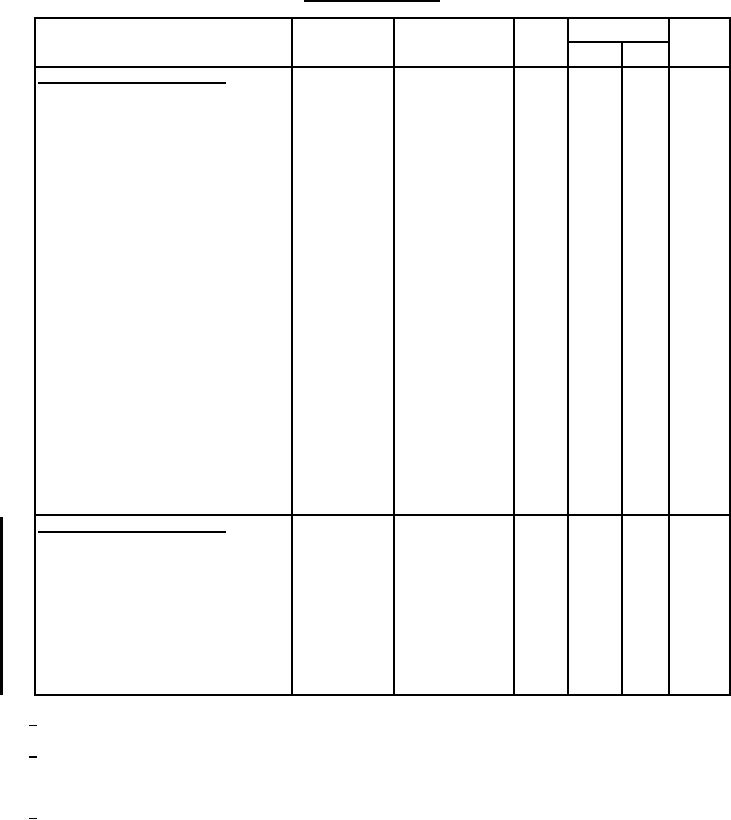

TABLE I. Testing and inspection - Continued.

Limits

MIL-STD-1311

Inspection

Unit

Conditions

Symbol

Method

Min

Max

Conformance inspection, part 2

Heater current

1301

If

540

660

mA

µA dc

Electrode current (anode No.1)

5201

Ec1 = 0

Ib1

-15

15

µA dc

Electrode current (anode No. 2)

5201

Light = 15 fL

Ib2

----

800

2

(51.4 cd/m )

µA dc

Electrode current (cathode)

5201

Light = 15 fL

Ik

----

1,000

2

(51.4 cd/m )

Base alignment (electrostatic types)

5101

+1D2, pin No. 5

----

----

----

----

Angle between traces

5101

----

89.2

90.8

Degrees

Neck and base alignment (electrostatic

5101

----

----

----

----

types)

Stray light emission (conventional types)

5216

Eb2 = 6,600 V

----

----

----

----

Line width "A" (electrostatic deflection)

5226

Light = 15 fL

Width

----

0.8

mm

2

(51.4 cd/m )

Line width "B" (electrostatic deflection)

5226

Light = 15 fL

Width

----

0.85

mm

2

(51.4 cd/m )

Focusing voltage at cutoff

5246

Eb1

----

300

V dc

Focusing voltage (zero-bias)

5246

Eb1

0

----

V dc

Deflection factor

5248

1D2

DF

40

50

V dc/in.

3D4

DF

20

25

V dc/in.

Heater-cathode leakage current

5251

----

----

----

----

Conformance inspection, part 3

Life-test provisions

----

Group C

t

500

hrs.

Eb2 = 2,500 V

Light = 15 fL

2

(51.4 cd/m )

Life-test end points

----

Same conditions

as initial tests

Line width "A"

Width

----

0.80

mm

Line width "B"

Width

----

0.85

mm

ĆEc

Modulation

----

45

V dc

1/

This test to be performed at the conclusion of the holding period.

2/

All portions of a raster pattern, adjusted so its widest points just touch the sides of a 2.5 by 4.0-inch (63.5 by

101.6 mm) rectangle, will fall within the area bounded by the 2.5 by 4.0-inch (63.5 by 101.6 mm) rectangle and

an inscribed 2.420 by 3.912-inch (61.47 by 99.36 mm) rectangle.

3/

The useful scan in the 1D2 and 3D4 directions is measured from the tube face center.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business