MIL-PRF-1/1005E

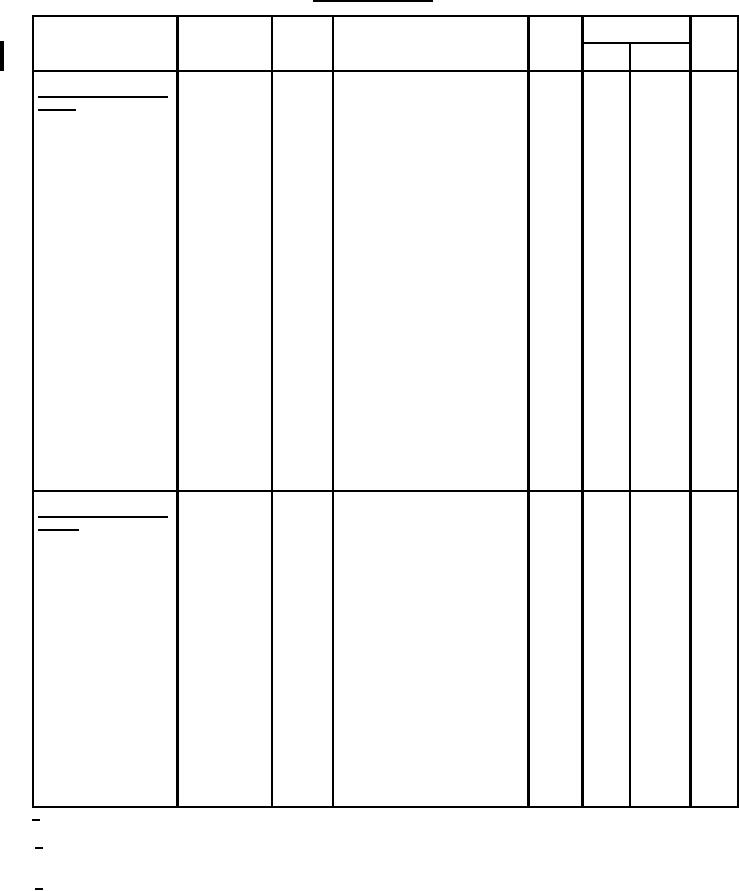

TABLE I. Testing and inspection - Continued.

Inspection

Method

Notes

Conditions

Symbol

Unit

Limits

MIL-STD-1311

Min

Max

Conformance inspection

part 2

Secureness of base,

1101

---

---

---

---

---

cap, or insert

Heater current

1301

---

If

540

660

mA

Heater-cathode leakage

5251

---

---

---

---

---

current

Screens

5221

---

---

---

---

---

Stray emissions

5216

---

Eb2 = 13,200 V dc;

---

---

---

---

Ec2 = 600 V dc;

Eb1 = 0

μA dc

Electrode currents

5201

---

Ec1 = 0

Ic2

-15

+15

(Grid No. 2)

Grid No. 2 leakage

5251

---

---

---

---

---

current

Neck and bulb alignment

5101

---

---

---

---

---

Side terminal and base

5101

---

Pin No. 3

---

---

---

---

alignment

Base pin solder depth

1111

---

---

---

---

---

Permanence of marking

1105

---

---

---

---

---

Conformance inspection

part 3

Life test

---

---

Group C; t = 500 hours (min);

---

---

---

---

Eb2 = 13,200 V dc;

Ec2 = 600 V dc;

Eb1 = focus;

Ib2 = 60 μA dc

Life-test end ponts:

---

lb2 = 100 μA dc

ΔEc1

Modulation

5223

---

---

32

V dc

Ib2 = 100 μA dc

Line width A

5226

---

Width

---

0.55

mm

Heater-cathode

5251

---

---

---

---

---

leakage current

Grid No. 1 leakage

5251

---

---

---

---

---

current

Grid No. 2 leakage

5251

---

---

---

---

---

current

Anode No. 1 leakage

5251

---

---

---

---

---

current

Stray light emission

5216

---

---

---

---

---

(conventional types)

1/ When Ec2 is greater than 330 V dc, Rg1 shall not exceed 0.5 MegΩ. When Ec2 is less than 330 V dc, Rg1 shall not exceed

1.5 MegΩ.

2/ The neck and base straightness shall be determined by the insertion of the tube neck in a cylinder 5 inches (127.00 mm) long

and 1.500 +.003, -.000 inches (38.10 +0.08, -0.00 mm) inside diameter. This cylinder should move freely between the

reference line and the base of the assembled tube.

3/ The raster shall overscan the tube face. The centerline of the raster shall be adjusted for best focus.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business