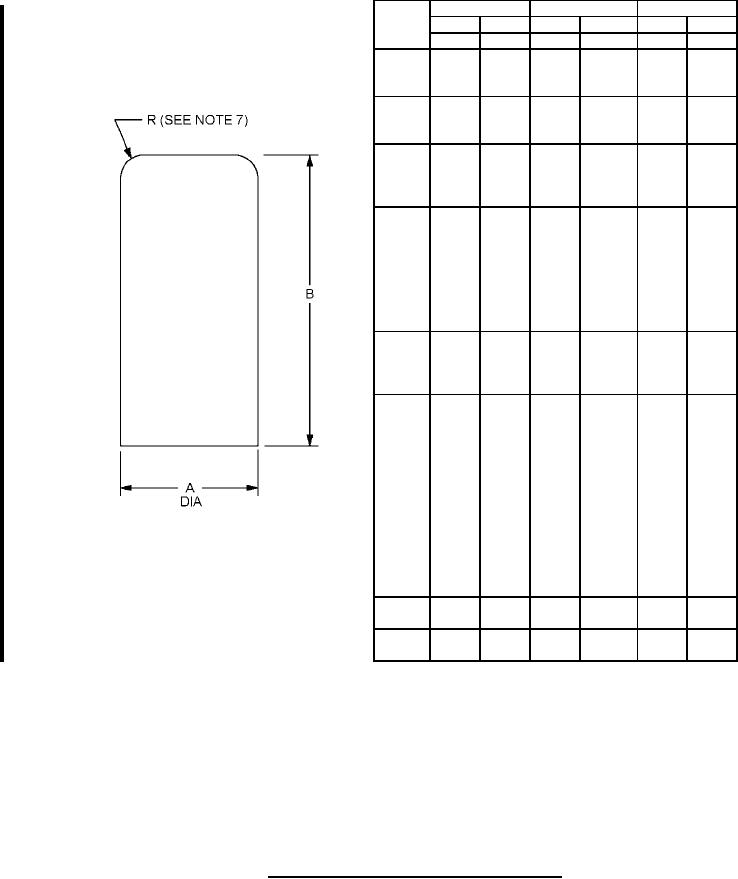

MIL-DTL-24251F

Tube

A

B

R

outline

in

mm

in

mm

in

mm

±.001

±0.25

±.010

±0.25

±.031

±0.79

1.100

27.94

T3

.380

9.65

1.400

35.56

.080

2.03

1.625

41.28

1.125

28.58

T5 1/2

.730

18.54

1.500

38.10

.156

3.96

2.000

50.80

1.125

28.58

1.562

39.67

T6 1/2

.840

21.34

.281

7.14

2.000

50.80

2.437

61.90

1.750

44.45

2.062

52.37

2.312

58.72

2.500

63.50

T9

1.150

29.21

.400

10.16

2.688

68.28

2.750

69.85

3.062

77.77

3.250

82.55

2.937

74.60

3.312

84.12

T11

1.410

35.81

.470

11.94

3.687

93.65

4.062

103.17

2.375

60.33

2.500

63.50

2.625

66.68

2.750

69.85

2.938

74.63

3.000

76.20

T12

1.560

39.62

.500

12.70

3.125

79.38

3.250

82.55

3.312

84.12

3.500

88.90

3.688

93.68

3.750

95.25

3.875

98.43

4.125

104.78

T14

1.830

46.48

.590

14.99

4.813

122.20

T16

2.050

52.07

4.175

106.05

.650

16.51

4.750

120.65

NOTES:

1. Dimensions are in inches.

2. Millimeters are in parentheses.

3. Metric equivalents are given for general information only and are based upon 1.00 inch = 2.54 mm.

4. Material: Tool steel, hardened to 56-61C.

5. Finish: Hard chrome plate.

6. Mounting method optional (screw and pins).

7. Radius shall be blended smoothly into A diameter.

FIGURE 1. Test slugs for installation and removal force tests.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business