MIL-DTL-24251F

4.4.1.3.1 Sampling plan. Statistical sampling and inspection shall be performed on an inspection lot basis with a

random sample of components selected in accordance with table II. The acceptance levels shall be based upon the

zero defective sampling plan. No failures shall be permitted.

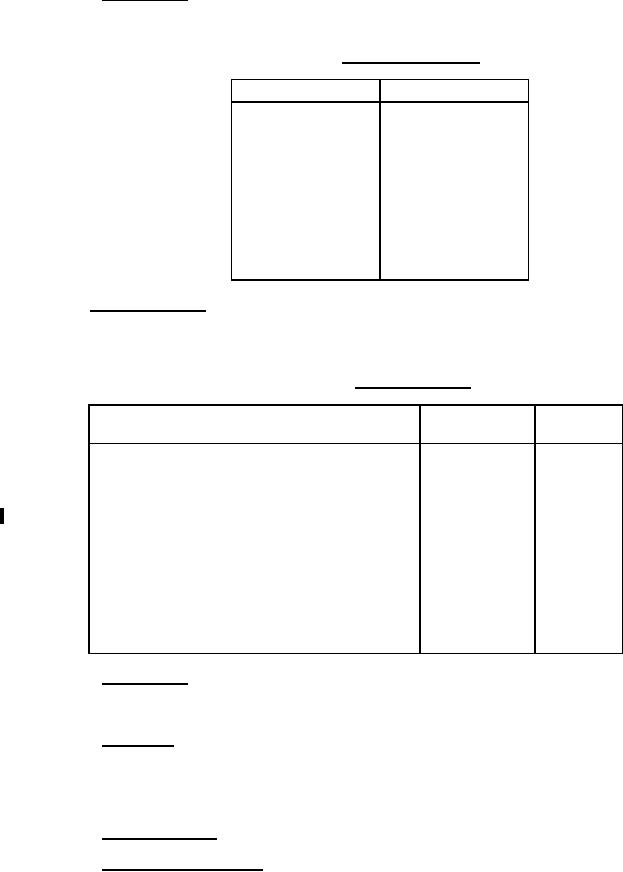

TABLE II. Group A sampling plan.

Lot size

Sample size

1-

13

100 percent

14 -

150

13

151 -

280

20

281 -

500

29

501 - 1,200

34

1,201 - 3,200

42

3,201 - 10,000

50

10,001 - 35,000

60

35,001 - 150,000

74

150,001 - 500,000

90

500,001 and over

102

4.4.1.4 Group B inspection. Group B inspection shall consist of the inspections specified in table III, in the order

shown, and the sample shall be selected from inspection lots that have passed group A inspection. NOTE: If the

following group B tests have previously been performed by the tube shield manufacturer, and if the material,

manufacturing process, and test requirements are the same as when these tests were initially performed, the subject

test(s) need not be performed again.

TABLE III. Group B inspection.

Requirement

Method

Test

paragraph

paragraph

Heat resistance - - - - - - - - - - - - - - - - - - - - - - - - - -

Heat dissipation - - - - - - - - - - - - - - - - - - - - - - - - -

Permeability - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Installation and removal - - - - - - - - - - - - - - - - - - - -

Salt atmosphere (corrosion) - - - - - - - - - - - - - - - - -

Electrical contact - - - - - - - - - - - - - - - - - - - - - - - - -

Installation, locking and unlocking torque or load,

and removal force - - - - - - - - - - - - - - - - - - - - - - -

Initial force at 25°C - - - - - - - - - - - - - - - - - - - - -

Force at temperature extremes - - - - - - - - - - - - -

Fatigue - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Vibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Shock - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

4.4.1.4.1 Sampling plan. Sample units shall be selected from tube shields, retainers (bases), or adapters that

have passed group A inspection. Two sample units shall be selected and tested every 24 months. The period shall

start the date the last test was satisfactorily completed on each of the individual units and run for 24 months.

4.4.1.4.2 Test routine. Group B inspection shall be performed at the start of production, and each 24-month period

thereafter. If production of a particular shield, retainer (base), or adapter has been suspended for 24 months or more,

group B inspection shall be again required at the time production is started. In such a case, inspection shall be

performed on sample units selected from the first lot of the new production presented for acceptance, and after each

subsequent 24-month period.

4.4.1.4.3 Acceptance criteria. No failures shall be permitted.

4.4.1.4.4 Disposition of sample units. Sample units which have been subjected to group B inspection shall not be

delivered on contract or order.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business