MIL-DTL-24251F

4.5.7 Heat dissipation (see 3.9). An instrumented glass tube (see appendix A and figure A-1) shall be used. The

glass material and dimensions shall be identical to those of the envelope size for which the tube shield is designed

(see table IV). The instrumented tube shall be mounted vertically in the appropriate MIL-DTL-12883 socket, which is

mounted with the proper retainer (base) or adapter (when applicable), on a heat sink which is maintained at a

temperature of 25°C ± 5°C.

4.5.7.1 Envelope stabilization. These measurements shall be made in an ambient temperature of 25°C ± 5°C, and

with no draft on the test setup. Temperature shall be measured with a bridge null detecting device with the tube

mounted in the socket on a constant temperature (25°C ± 5°C) heat sink under a 1 x 1 x 1 foot plastic cover. The

instrumented tube (see appendix A) shall be wired into the circuit shown on figure 2 with the heater voltage adjusted

to the required nominal voltage. Plate voltage shall be as shown in table IV. The grid bias shall be adjusted to

increase the plate current until both the total dissipation watts (within the range specified in table IV) and the bare

bulb temperature (within the tolerance specified in table IV), are reached. The stabilized bulb temperature as

indicated by the bulb thermocouple shall be recorded. The shield assembly shall be mounted on its base. The

stabilized bulb temperature with the shield mounted shall again be recorded. The shield shall be rotated to at least

two other different positions, except those shields which have only two rotatable positions, which shall be only one

other position. Measurements shall be repeated for each increment of rotation. During the test, the heat sink and

ambient temperatures for each separate shield test shall be recorded.

4.5.8 Salt atmosphere (corrosion). Shields and associated parts shall be tested in accordance with method 101,

test condition B, of MIL-STD-202. Upon completion of the test, the shields and associated parts shall be examined

for evidence of corrosion or other defects as specified in 3.10.

4.5.9 Electrical contact. The shield retainer (base), adapter, and socket shall be mounted to a bare metal chassis

in the normal manner. An appropriate tube shall be mounted in the assembly. The protective coating may be

removed from a point on the upper part of the shield so that good electrical contact may be made with the ohmmeter

probe. The resistance shall be measured between shield and chassis using an ohmmeter having an accuracy of ±3

percent of indication or better (see 3.11).

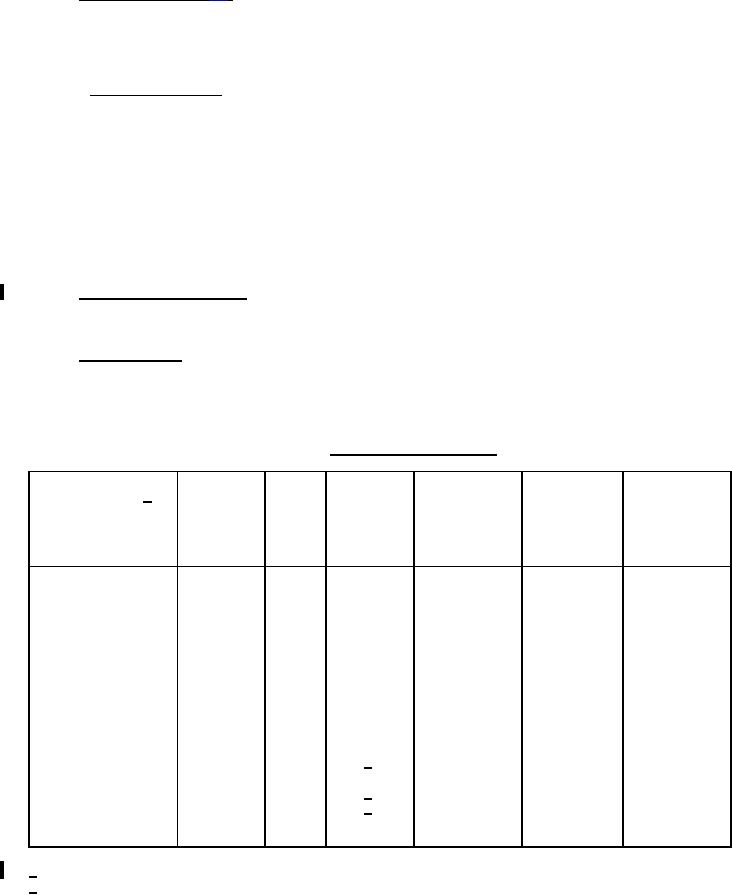

TABLE IV. Instrument tube parameters.

Total

Envelope size 1/

Tube type

Test

Plate

Plate

dissipation

Bare bulb

circuit

voltage

current

(filament

temperature

(± 5°C)

Ep-dc

dc milli-amps

and plate)

volts

(max/plate)

Nominal-

watts ±10%

maximum

T2x3 (flat bulb) - - - -

6029

7

135

---

1.14

100

T3 (round bulb, 8 pin)

5902

7

150

---

6.19

220

T3 (flat press, 7 pin-

in-line) - - - - - - - - -

5702WB

7

150

---

2.67

145

T5-1/2 short - - - - - -

5654

1

130

---

3.1

115

T5-1/2 medium - - - -

6AN5WA

1

130

---

9.1

215

T5-1/2 long - - - - - - -

6005

2

250

---

12.9

240

T6-1/2 short - - - - - -

5670

250

4.8

130

3

---

T6-1/2 medium - - - -

5687WA

200

13.2

225

4

---

T6-1/2 long - - - - - - -

6216

200

18

230

5

---

T6-1/2 ex-long- - - - -

7189A

250

19.5

235

6

---

2/

T9 - - - - - - - - - - - - -

5Y3WGTA

23.5

225

290

8

300

T11 - - - - - - - - - - - -

6L6WGB

33.1

250

---

7

2/

T12 - - - - - - - - - - - -

5U4GB

32.7

200

700

8

2/

T14 - - - - - - - - - - - -

5R4WGB

45.5

250

490

8

300

T16 - - - - - - - - - - - -

6336A

54.3

250

---

9

1/ Conforming ECA-RS209.

2/ Current limitation.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business