MIL-PRF-1/970F

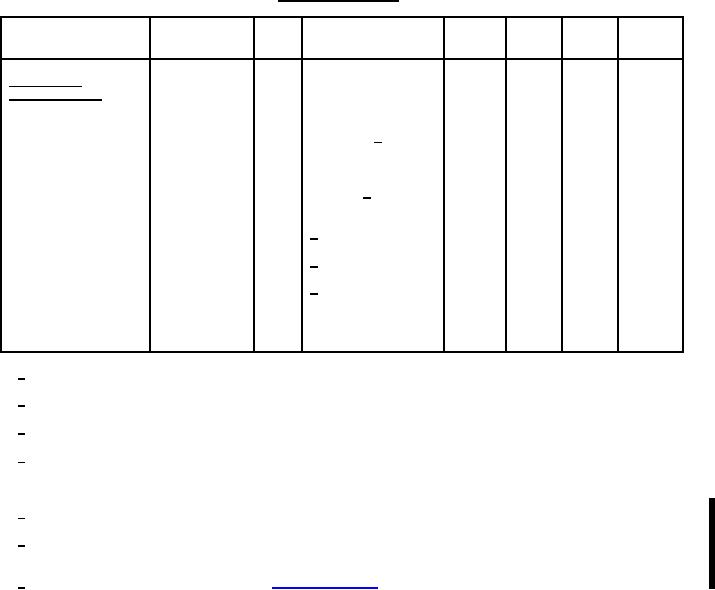

TABLE I. Testing and inspection Continued.

Requirement or test

Method

Test

Conditions

Symbol

Limits

Limits

Unit

MIL-STD-1311

Min

Max

Conformance

inspection, part 3

t

500

---

hrs

Life test

---

3

Group D; li = 150 to

200 A dc 2/

Life test end points:

---

Insertion loss

4416

---

F4; li = 0 1/

Li

---

1.0

dB

(fixed tuned)

Spike-leakage energy

4452

1

2/

Ws

---

0.3

erg

Flat-leakage power

4452

1

2/

pf

---

40

mW

s

Recovery time

4471

3

2/

t

---

30

Temperature cycling

1027

---

Group C; 10 cycles

---

---

---

---

life-test end point

1/ This test shall be performed using the flanges specified in Drawing 268-JAN.

2/ This test shall be performed using the mount specified in Drawing 153-JAN or equivalent.

3/ A swept frequency method of measurement may be used instead of measurement at fixed frequencies.

4/ The tube shall be mounted in accordance with Drawing 208-JAN, and the complete assembly cycled once from -55C to

+100C. After the temperature has again reached room temperature, the pressure shall not have changed more than one-

2

quarter of a pound/in as indicated by a gauge permanently connected into the system.

5/ This specification sheet uses accept on zero defect sampling plan in accordance with MIL-PRF-1, table III.

6/ The tube shall be capable of being inserted and removed from the mount specified in Drawing 153-JAN or equivalent a

minimum of 15 times with no deterioration in the tube's electrical characteristics.

7/ To obtain copies of the JAN drawings e-mail TubeAmps@dla.mil group except for drawing 153-JAN.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business