MIL-PRF-1/943E

TABLE I. Testing and inspection - Continued.

12/

For this test, the light source shall be a square wave modulated at 90 Hz. Diameter of the light spot shall be 1.25 inch (31.75

mm). Output of the tube shall be fed into a low-pass amplifier, the bandwidth of which is 1,000 Hz. The amplifier output shall

be read with a vu meter calibrated in dB. Amplifier attenuator is also calibrated in dB. Prior to testing, tubes shall be held at

an ambient temperature of 75°F ± 5°F for not less than 1 hour in the dark.

a.

Signal: With light on, adjust attenuator so that vu meter is at zero. Read attenuator setting.

b.

Noise: Read as above with light off.

c.

S/N ratio = Signal (dB) - Noise (dB).

13/

Capacitance between anode and dynode No. 10, all other elements grounded.

14/

Capacitance between anode and all other elements.

15/

Ebb = 1,000 volts, adjust luminous flux at the cathode initially to obtain Ib = 0.75 mA dc. Color temperature shall be greater

than 2,000°K.

Life-test end-point is either an Ib of 20 µA or a decrease of 5% of the initial Ib, whichever is reached first.

16/

17/

Test circuit and test equipment requirements.

A bleeder network to provide 16.67% of the overall voltage between cathode and dynode No. 1 and 8.33% of the overall

voltage for each succeeding stage; 8-megohm series resistance for cathode, and all dynodes excluding the last dynode

(10th); 1-megohm series resistance for last dynode (10th) and anode; a regulated (0.1 percent) power supply with low-ripple

(0.05 volts peak-to-peak maximum) as a voltage source; a sensitive dc microammeter to determine anode current; an

oscilloscope, with a low-capacity divider, is connected across the anode load resistance (1-megohm) to monitor noise and

breakdown; base pins of photomultiplier under test connected so that the degradation of breakdown characteristic is

minimized; a vacuum pump, low-pressure chamber and manometer; a light source with an adjustable iris and sandblasted

glass.

Test method.

Mask tube with light proof material. The light-source should be located so that light from it is striking the cathode of the

photomultiplier. (Light from the light source should be the only light striking the cathode.) The opening of the iris is varied to

obtain approximately 10 microamperes of anode current. Observe the tube-noise signal as displayed by the oscilloscope.

Reduce pressure of vacuum chamber to 130 millimeters of mercury. The tube should be subjected to this pressure for a

period of 2 minutes. During pressure reduction, the tube noise signal, as displayed by the oscilloscope, should be observed

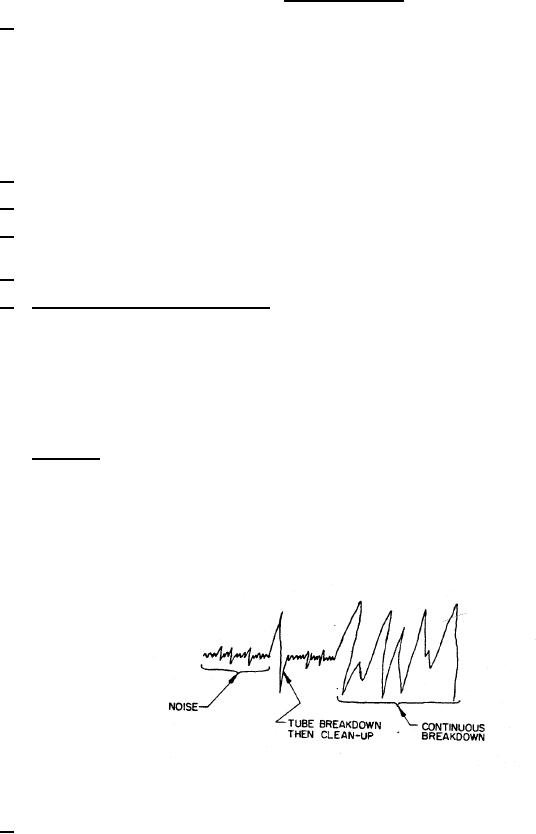

to determine tube breakdown. When breakdown occurs, the signal being monitored by the oscilloscope will resemble the

following:

When continuous breakdown occurs, a change in anode current will result.

18/

An ac supply voltage may be used having a peak value equal to this maximum value.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business