MIL-PRF-1/877E

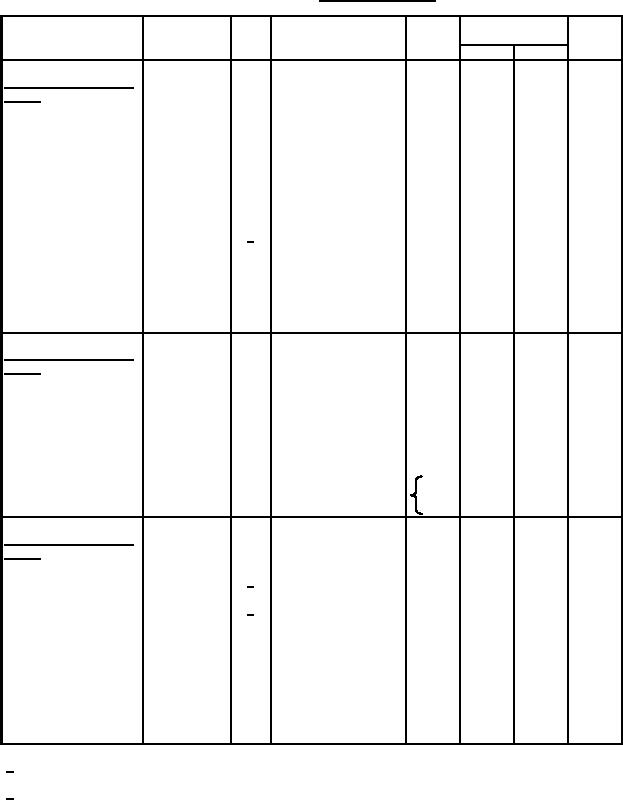

TABLE I. Testing and inspection.

Inspection

Method

Notes

Conditions

Symbol

Limits

Unit

MIL-STD-1311

Min

Max

Conformance inspection,

part 1

5.8

6.6

A ac

If Ec(1)

Filament current

---

1301

Electrode voltage (1)

---

1261

Ec(2)

V dc

-34.0

-46.0

(grid)

Ic

Electrode voltage (2)

---

Eb = 14.0 kV dc;

1261

V dc

---

-550

(grid)

Ec/Ib = 1.0 mA dc

Isg

Total grid current

1/

1266

---

-10

ľA dc

1266

---

Ic = 100 mA dc;

---

-500

ľA dc

Primary grid emission

is

t = 15 seconds;

Ef = 5.5 V ac

---

eb = ec = 2,500 v

1231

3.0

---

a

Peak emission

Conformance inspection,

part 2

1316

Amplification factor

---

Mu

34.0

42.0

---

W

Power oscillation

1236

---

Po

270

---

F = 8 MHz;

(useful)

Eb = 3,000 V dc;

Ib = 150 mA dc

pF

1331

Direct-interelectrode

---

1.7

2.3

Cgp

pF

capacitance

2.5

3.4

Cin

pF

---

0.45

Cout

Conformance inspection,

part 3

Low-frequency vibration

1031

2/

No voltages applied

---

---

---

---

Bump

1036

2/

---

---

---

---

Angle = 10°

Life test

---

---

Group C; power

---

---

---

---

oscillation;

t = 500 hours

---

---

Life-test end points:

Peak emission

1231

---

is

2.5

---

a

Primary grid emission

1266

---

Isg

---

-500

ľA dc

1/ This test is to be the first test performed at the conclusion of the holding period.

2/ This test shall be performed during the initial production and once each succeeding 12-calendar months in which there is

production. A regular double sampling plan shall be used, with the first sample of three tubes with an acceptance number of zero,

and a second sample of three tubes with a combined acceptance number of zero. In the event of failure, the test will be made as a

part of conformance inspection, part 2, code level D, with an acceptance level of 6.5. The regular "12-calendar month" double

sampling plan shall be reinstated after three consecutive samples have been accepted.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business