MIL-PRF-1/868F

Dimensions in inches with metric

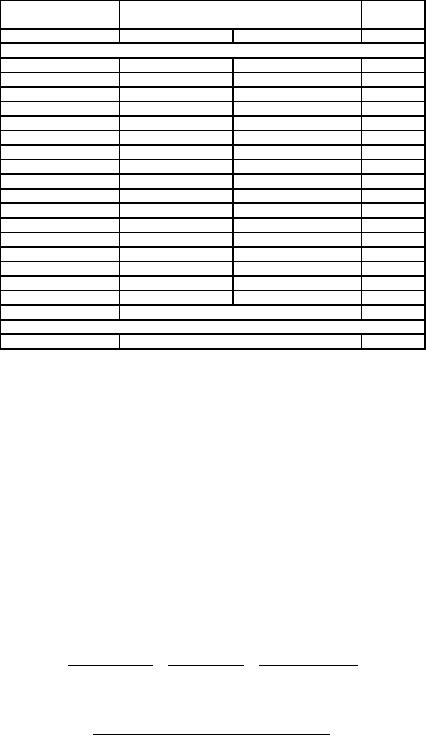

Ltr

Notes

equivalents (mm) in parentheses

Minimum

Maximum

Conformance inspection, part 2

A

2.562 (65.07)

a

B

1.973 (50.11)

C

1.220 (30.99)

1.260 (32.00)

D

.850(21.59)

.880(22.35)

E

.395(10.03)

.455(11.56)

a

F

.475(12.07)

.505(12.83)

G

.360( 9.14)

.390( 9.91)

H

.180( 4.57)

.210( 5.33)

a

J

.360( 9.14)

.390( 9.91)

a

K

.030( .76)

.035( .89)

a

L

.242( 6.15)

.258( 6.55)

M

.248( 6.30)

.252( 6.40)

P

.016( .41)

.047( 1.19)

a

R

.557(14.15)

.567(14.40)

a

S

.808(20.52)

.816(20.73)

T

1.023 (25.98)

1.039 (26.39)

U

1.216 (30.89)

1.236 (31.39)

a

V

B6-108

Reference dimensions

N

45°

Notes:

a. These dimensions shall be inspection on 10 tubes a month when in continuous production. Failure of

one tube to meet tolerances for any dimensions shall cause that dimension to become for

all lots in process, part of conformance inspection, part 2.

b.

External glass surface of tube shall conform to the detailed requirements of figure 1. Conformance inspection,

part 2 shall apply.

c.

Cathode rf contact surface shall be free from welding flash material, Conformance inspection,

part 2 shall apply.

d.

Limits of dimension U do not apply at points where skirt is crimped to base.

e.

Radius with limits as specified may be used instead of chamfer.

f.

External metal surfaces, except base pins, shall be silver plated 30msi, minimum. Conformance inspection,

part 2, shall apply.

g.

Eccentricity of contact surfaces shall be as follows. Conformance inspection, part 2, shall apply.

Contact surface

TIR maximum

Reference surface

Grid

.016

Anode cap

Cathode, rf

.016

Grid

FIGURE 1. Outline drawing of electron tube type 2C40A. Continued.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business