MIL-PRF-1/868F

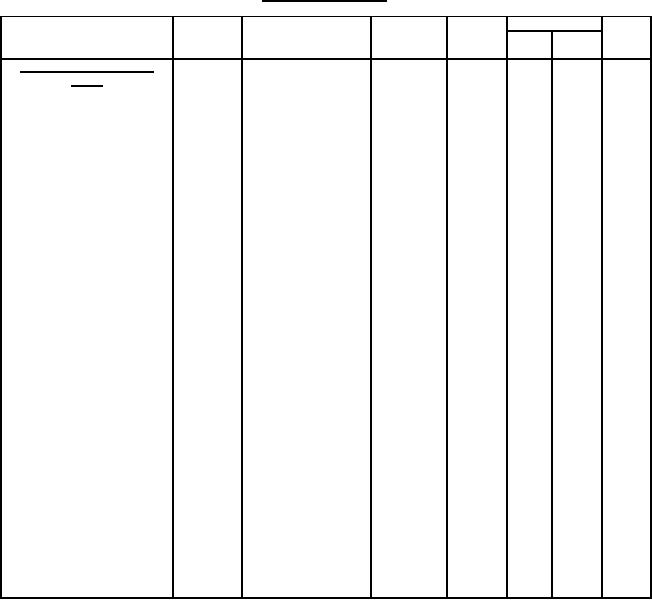

TABLE I. Testing and Inspection Continued

Limits

Method

Acceptance

Inspection

Conditions

Symbol

Unit

MIL-STD-

level

Min

Max

1311

note 8

Conformance inspection,

part 3

---

---

---

---

---

Life-test (1)

---

Group A

Eb = 300 Vdc;

Rk/Ib = 17 mAdc;

t = 500 hours

Life-test (1) end point:

---

Power oscillation (cw)

1236

---

Po

25

---

mW

---

---

---

---

---

Life-test (2)

---

Group C;

power oscillation

(pulsed) except

prr = 2,000 ±10%

t = 500 hours

Life-test (2)

Life-test (2) end point

---

---

Po

300

---

mW

conditions

---

Ep

---

100

mV

High-frequency vibration

1031

F = 50 Hz; 10G;

Ebb = 300 V dc;

Rp = 10,000 ohms;

Ec/Ib = 10 mA dc

Notes 4, 5 and 7

---

---

20

---

lb-in

Secureness of base,

1101

No voltages;

cap, or insert

torque to be

applied between

anode and pins

without shock

Notes 4 and 7

Torque-test end point

---

Total grid current

1266

Note 7

---

Ic

---

-0.5

A dc

Frequency draft

---

Notes 4, 6 and 7

---

F

---

2.0

MHz

NOTES:

1.

The following test methods shall not apply: MIL-STD-1311 Methods 1006 and 1201.

2.

The pulse shape shall be in accordance with method 1296. Minimum power output limit, based on a duty factor of 0.001,

may be adjusted for the exact duty factor used. Coupling and tuning to be adjusted for maximum power output. The tube

shall operate under the given conditions and minimum output, or greater, for a minimum of 30 seconds without arcing or

instability as evidenced by pronounced variations in the average anode current meter or the power output meter. If

temporary arcing does occur during the 30-second period, the tube must subsequently operate for 60 seconds without

arcing. The test may be discontinued, at the end of the 30-second period, if the power output has not completely stabilized

but is rising. If the power output is falling, the test is continued until a stable reading is obtained. For qualification approval,

a stable reading shall be obtained.

3.

The starting voltage is measured by raising the pulsed anode voltage from zero and noting the voltage at which a readable

indication is obtained on the power meter. The tube may not be oscillating during the full width of the modulation pulse

during this test.

4.

Test 10 tubes selected at random from the first production lot of each calendar year, and approximately every 90 days of

production during the year. If one tube fails to pass the specified end point, the failed test shall become a part of

conformance inspection, part 2, on all lots in process. After three consecutive successful submissions, the test shall revert

to the 10-tube quarterly test.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business