MIL-PRF-1/849G

TABLE I. Testing and inspection - Continued.

20/ An airflow of 10 cubic feet per minute (cfm) at approximately 760 mmHg shall be directed on the cooling fins from an orifice 2-1/2

inches by 1-3/16 inches (63.50 mm by 30.16 mm). Temperature of the anode shall be measured, and the rise shall not exceed the

amount specified.

21/ The tube shall be operated into a transmission line with a VSWR of 1.5:1 minimum adjusted in phase to produce the maximum

spectrum degradation.

22/ The rrv shall be expressed in kv per Ps defined by the steepest tangent to the leading edge of the voltage pulse above 80 percent

amplitude. Any capacitance used in viewing system shall not exceed 6.0 pF. No spike or ripple shall exceed r7 percent of the

average peak value of voltage or current. Inverse voltage shall not exceed 20 percent of the forward voltage. The negative

amplitude of any post pulse voltage oscillation shall not exceed 10 percent of the average peak value.

23/ The VSWR shall be adjusted to the phase producing maximum instability and the MP counted for a period of 3 minutes starting 30

seconds after application of high voltage.

24/ In addition to regular markings, letters and dial settings shall be stamped on the tube at the point specified on figure 1, to indicate

F1 through F5 r 10 MHz at the start of life under test condition 2 conditions with the body temperature 70q r10qC.

25/ All of the requirements of test conditions 1 and 2 shall be met with the heater voltage at r8 percent from the voltage specified for

test.

26/ Life test shall be run with heater power frequency set at the major resonant frequency, if any, as determined by the heater structure

type test, provided the resonant frequency occurs at 55 to 65 Hz or in the interval 340 to 1,800 Hz. If there is no such resonant

frequency, heater power may be at any convenient frequency up to 1,800 Hz at the discretion of the manufacturer. To measure the

resonant frequency, one of the two following methods shall be used:

(a) Supply the specified preheating voltage to the tube heater from a variable frequency power supply. Vary the supply

frequency while listening (with a sensitive stethoscope) for any indication of resonance. At the resonant frequency distinct

vibration of the structure will be heard.

(b) Supply heater voltage to the tube from a variable frequency supply. Operate the tube (test conditions 1) and observe the

RF spectrum while varying the frequency of the heater voltage. At the resonant frequency of the heater cathode structure,

large values of the frequency modulation will be observed.

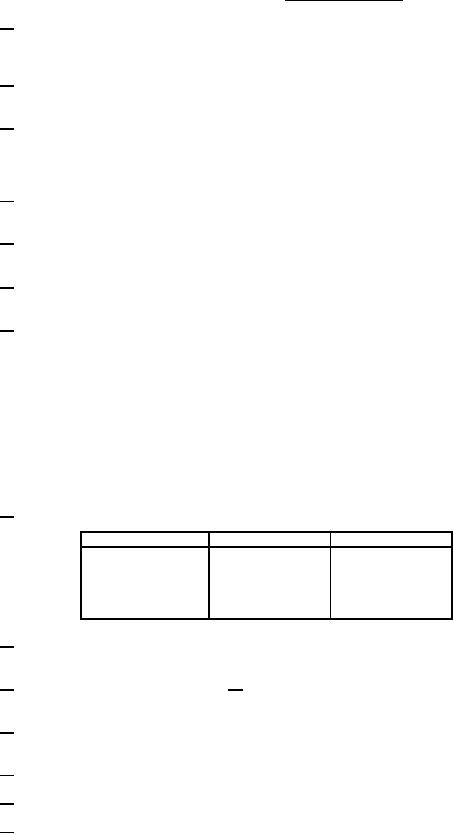

27/ Life test shall be conducted in accordance with the following cycle:

Test condition

Ef (V)

Duration

Standby

12.6

2 minutes

1

10.4

3 minutes

2

7.8

15 minutes

Off

----

16 minutes

28/ If during life test the tube does not meet the specified limits, it shall be recycled for an additional 5 cycles. At such time the test shall

be repeated. If the tube fails the second test, it shall be considered unsatisfactory.

29/ At each of the dial settings called for in 24/, the measured frequency shall not differ from the stated frequency by more than the

amount specified.

30/ 5 G or DA = .01 inch, whichever is limiting value. Vibration frequency = 5 to 500 to 5 Hz varied uniformly over complete range in 15

minutes, repeat for a total of 2 hours in each of three axes.

31/ Duration of each cycle = 45 seconds (maximum).

32/ For vibration tests, axes of vibration shall be reference axes "A", "B", and "C".

33/ Reference point for anode T measurements locate where a central fin meets the anode block near the output section.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business