MIL-PRF-1/810E

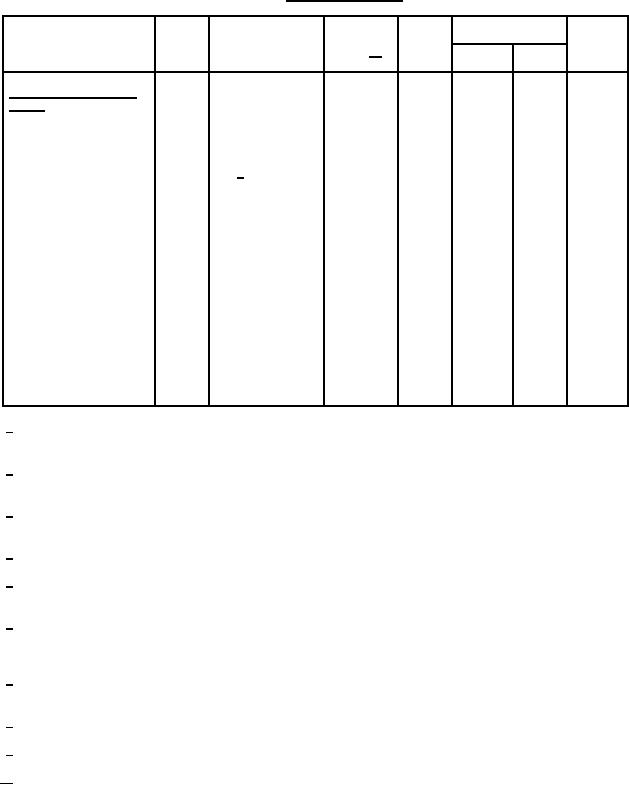

TABLE I. Testing and inspection - Continued.

Acceptance

Limits

Inspection

Method

Conditions

Level 10/

Symbol

Unit

Min

Max

Conformance inspection,

part 3 - Continued

Deflection-factor

5248

---

---

---

2

%

uniformity

Deflection defocusing

---

6/

---

---

---

1:2

Ratio

Magnetization

5256

---

---

---

---

---

Direct-interelectrode

1331

8/

capacitance

g1 to all

---

Cg1

---

5.0

pF

k to all

---

Ck

---

4.1

pF

D1 to D2

---

C1D2

---

2.2

pF

D3 to D4

---

C3D4

---

1.5

pF

D1 to all

---

CD1

---

5.4

pF

D2 to all

---

CD2

---

6.1

pF

D3 to all

---

CD3

---

4.5

pF

D4 to all

---

CD4

---

3.9

pF

Pressure (implosion)

1141

---

---

---

---

---

Vibration

5111

---

Width

---

1.0

mm

1/

Accelerator to final intensifier electrode voltage equally divided over the three intensifier electrodes by 25 megohm resistors

connected between each intensifier and the accelerator.

2/

It is recommended that the deflection electrode circuit resistances be 1 megohm, or less, and approximately equal, otherwise beam

shift at high drives can be expected. Higher resistance values up to 5 megohms may be used for low-beam current operation.

3/

This tube is designed for optimum performance when operating at an Eb3/Eb2 ratio of 4.5. Operation at other ratios of Eb3/Eb2

may result in changes in deflection uniformity and pattern distortion.

4/

Accelerator power input (average) shall be limited to 6 watts.

5/

ID2 deflection factor shall be within 8 volts of 3D4. The useful scan in the ID2 and 3D4 directions is plus or minus 2 inches (50.8

mm) from tube face center.

6/

The ratio of the line width of a 4 inch (101.6 mm) long trace, adjusted for best center focus, to the line width measured on the

faceplate axis when the trace is deflected perpendicularly plus or minus 2 inches (50.8 mm) from the face center by a balanced dc

voltage, shall not be greater than the value specified.

7/

All portions of a raster pattern, adjusted so its widest points just touch the sides of a 3.040 inch (77.22 mm) square, will fall within

the area bounded by the 3.040 inch (77.22 mm) square and an inscribed 2.960 inch (75.18 mm) square.

8/

All other electrodes contained within the envelope shall be tied together.

9/

This test to be performed at the conclusion of the holding period.

10/

This specification uses an acceptance zero (c = 0) sampling plan, in accordance with MIL-PRF-1, Table III.

4