MIL-PRF-1/796D

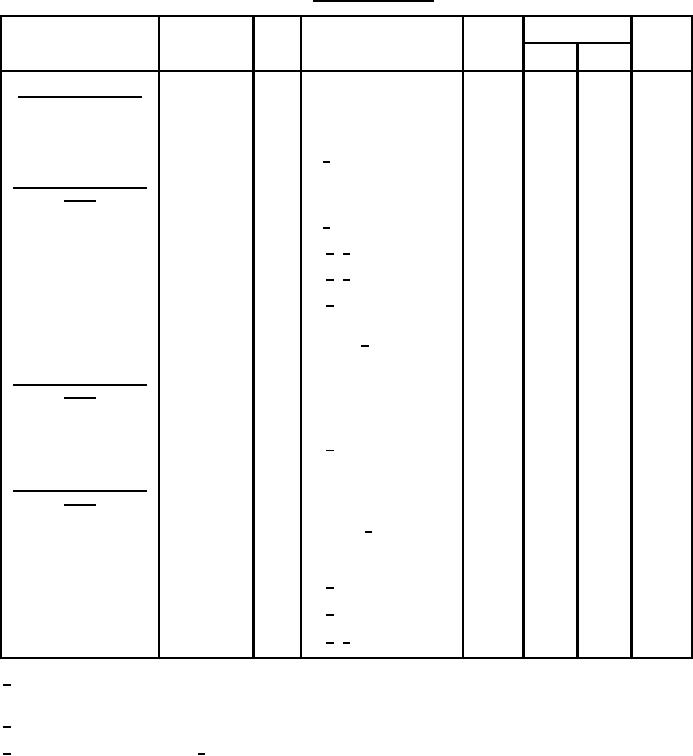

TABLE I. Testing and inspection.

Method

Limits

Inspection

MIL-STD-1311

Test

Conditions

Symbol

Unit

Min

Max

Qualification inspection

Degradation due to

4021

---

---

---

---

---

vibration

Loaded Q

4461

---

2/

QL

---

5.5

---

Conformance inspection,

part 1

Tuning susceptance

4482

----

2/

b

-0.05

+0.05

---

Firing time

4486

1

2/ 3/

t

---

10

sec

Arc loss

4488

1

2/ 3/

La

---

0.8

dB

Temperature cycling

1027

---

1/

---

---

---

---

(nonoperating)

Temperature cycling

1027

---

Group C 1/

---

50

---

Hz

life test

Conformance inspection,

part 2

High-level VSWR

4474

1

---

---

1.15

---

Normalized conductance

4484

---

2/

g

---

0.05

---

Conformance inspection,

part 3

Life test

4551

2

Group D

2/

t

1,000

---

hrs

Life-test end points:

---

---

Tuning susceptance

4482

---

2/

b

-0.05

+0.05

---

Normalized conductance

4484

---

2/

g

---

0.1

---

Firing time

4486

1

2/ 3/

t

---

10

sec

1/ Satisfactory test on any one of 1B44, 1B52, 1B53, 1B56, 1B57, 5921, or 5922 ATR tube types made during the same two week

period, shall be evidence that all of the group meet this test requirement.

2/ Mount in accordance with drawing 153-JAN.

3/ The tube shall be mounted as in 2/ and followed by a matched load. The tube shall fire within the limits specified after

application of rf power. This test shall be performed at least 7 days after pumping and at least 24 hours after any previous

discharge.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business