MIL-PRF-1/747F

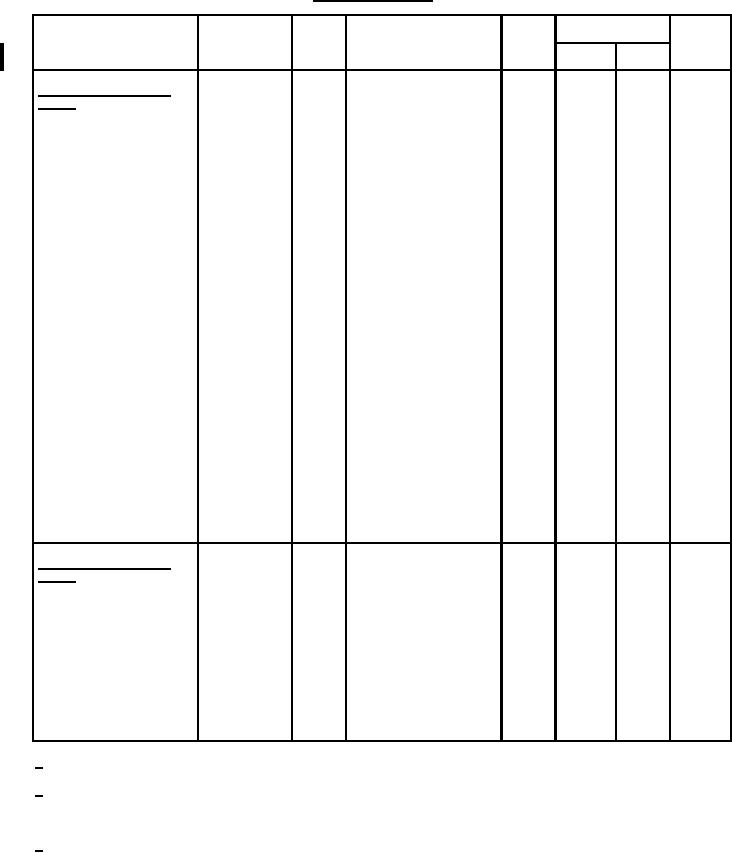

TABLE I. Testing and inspection - Continued.

Method

Limits

Inspection

MIL-STD-1311

Notes

Conditions

Symbol

Unit

Min

Max

Conformance inspection,

part 2

Heater current

1301

---

If

540

660

mA

µA dc

Electrode current

5201

---

Ec1 = 0

Ib1

-15

10

(anode No. 1)

Neck and base alignment

5101

---

---

---

---

---

(electrostatic types)

Angle between traces

5101

---

---

---

---

---

Cathode illumination

5216

---

---

---

---

---

Stray light emission

5216

---

Eb2 = 2,750 V dc

---

---

---

---

(conventional types)

Line width A

5226

---

Light = 20 ftL

Width

---

0.65

mm

(electrostatic deflection)

Line width B

5226

---

Light = 20 ftL

Width

---

0.65

mm

(electrostatic deflection)

Focusing voltage at cutoff

5246

---

Ec1 = cutoff

Eb1

---

700

V dc

Deflection factor

5248

---

1D2

DF

68

92

Vdc/inch

Deflection factor

5248

---

3D4

DF

28

38

Vdc/inch

Secureness of base, cap,

1101

---

---

---

---

---

or insert

Permanence of marking

1105

---

---

---

---

---

Conformance inspection,

part 3

Life test

---

---

Group C;

---

---

---

---

light = 20 ftL

Eb2 = 2,750 V dc;

t = 500 hrs (min)

Life-test end points:

---

Line width A

5226

---

Light = 16 ftL

Width

---

0.65

mm

Line width B

5226

---

Light = 16 ftL

Width

---

0.65

mm

ĆEC

Modulation

5223

---

Light = 16 ftL

---

38

V dc

1/

This value is recommended only for low-velocity deflecting and low-ambient light levels.

2/

All light dependent tests to be measured with a 1.125 inch (28.58 mm) vertical and 1.562 inch (39.69 mm) horizontal, 30-line

raster. Photocell is to have a 1-inch (25.40 mm) active aperture and calibrated in foot lamberts similar to Photovolt

Corporation type 200-A, or equal.

3/

This test to be performed at the conclusion of the holding period.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business