MIL-PRF-1/507H

NOTES - Continued

21

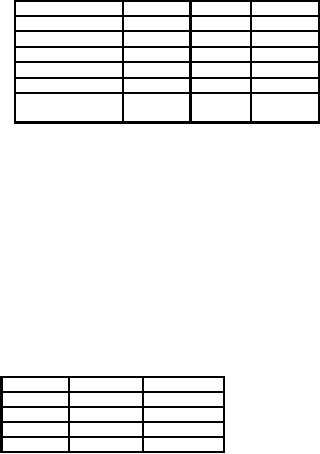

The pulse characteristics for Oscillation(1) test shall be as follows:

Min

Max

Unit

µsec

tpc

0.225

0.275

µsec

tfc

---

0.15

µsec

trv

0.09

0.14

±10

Ripple

---

%

±20

Inverse voltage

---

%

±5

Post pulse

---

%

forward voltage

22

The r-f bandwidth shall be within the limits specified when the specified VSW R is introduced in the load at a distance of

approximately 0.25 meter from the magnetron, with the load phase adjusted for maximum spectrum degradation.

23

Stability shall be measured in terms of the average number of output pulses missing, expressed as a percentage of the number of

input pulses applied during the period of observation. Output rf pulses are considered to be "missing" if, due to any causes, the

average rf. pulse energy, within a ±1 percent frequency range of the normal operating frequency, is less than 70 percent of the

energy level of a normal pulse. The percentage of missing pulses shall not exceed the amount specified, when measured in the

last 3 minutes of a test interval not to exceed 6 minutes. Observation shall be made at the load phase position corresponding to

maximum instability.

24

After subjection to Vibration test, each tube shall meet requirements for rf spectrum and stability in accordance with Oscillation (1)

testing requirements herein.

25

The pulling measurement test shall be made in a manner such that thermal effects do not contribute appreciable error.

26

One Life test cycle shall consist of operation under the conditions of Osc (1) testing, as follows:

Ef

Ib

Period

Volts

mA dc

Minutes

4.8

0

3

0

26

120

0

0

27

a. The input power to the heater shall be snapped on at the beginning of each Life test cycle with a surge current of 24 to 26

amperes RMS.

b. The standing wave introducer shall be moved during the test so that operation is obtained for load phase positions

corresponding to maximum power output, minimum power output, maximum frequency, and minimum frequency. If

automatically driven, the standing wave introducer shall be cycled continuously through a line length approximately one-half

wavelength long at a maximum rate of four cycles per hour; if manually moved, the standing wave introducer shall be cycled

through the four load phase positions corresponding to maximum power, minimum power, maximum frequency, and minimum

frequency at least once during the specified life of the tube, spending approximately equal periods of time in each phase

position.

27

This test shall be performed in such a manner as to exclude thermal effects. The frequency drift shall not exceed the amount

specified when averaged over each eight hour period during the minimum specified life, except during the first 24 hours. The

frequency drift during the first 24 hours shall not exceed 6.0 MHz per hour when averaged over each eight hour period.

28

For periodic tests, sample tubes are to be selected at random intervals so that during only twelve-month period a minimum of two

tubes shall have been successfully tested. In the event of failure of one or more tubes in a sample, these tests are to become a

part of Conformance Inspection, part 2, until two successive lots have been successfully completed on these tests. After two

successive lots have been successfully completed, the periodic tests shall then be eligible to be resumed on a twelve-month basis.

29

After subjection to all Periodic-check tests, the sample tube(s) shall meet the requirements of all tests in conformance inspection,

part 1 herein.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business