MIL-PRF-1/507H

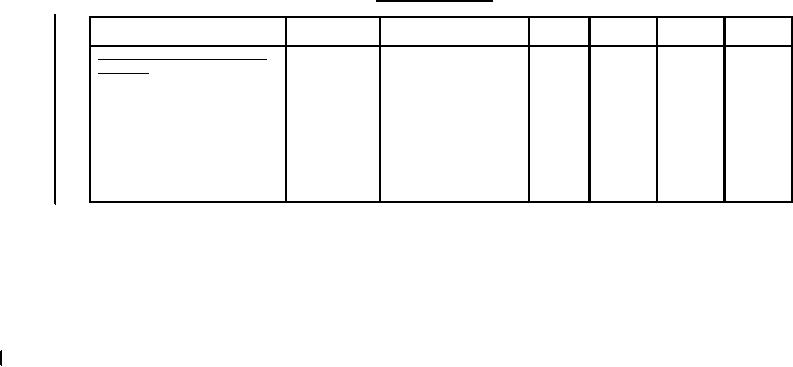

TABLE I. Testing and inspection - Continued.

*

Requirement or test

MIL-STD-1311

Conditions

Symbol

Limits

Limits

Units

Method

Min

Max

Conformance inspection, part 3 -

continued.

GHz

16.160

15.840

(Osc.(1))

F

---

Frequency

(notes 4, 19, 33)

°C

ĆT

+70

---

(Osc.(1))

---

Air cooling

TA = +25 °C

Pi = 624 W ±10%

Air flow = 40 cfm

(note 34)

NOTES:

1

Refer to MIL-PRF-1, section 3 definition of absolute ratings.

2

Prior to application of high voltage, the filament current applied should be between 10.8 and 13.2 amperes. The procedure should

include, first, applying 4.8 volts for 180 seconds minimum to filament; then, upon application of anode voltage, the heater voltage

should be reduced until the anode current is 26 mA dc.

3

The heater surge current should not be allowed to exceed 24 rms amperes.

4

Refer to figure 1, notes 12 and 21 herein for temperature-measurement point. Temperature shall be measured after thermal

equilibrium has been reached.

5

The characteristics of the applied pulse must be those which result in proper starting and oscillation. The rate of pulse voltage rise,

the percentage of pulse voltage ripple, and the rate of the pulse voltage fall are among the more important considerations. Negative

post-pulse voltage oscillations may cause leakage current and noise. The established pulse characteristics (refer to Oscillation (1)

pulse characteristics, herein) should be adhered to.

6

The gas used in pressurization shall provide insulating properties equal to or better than that of dry air at the pressure specified.

7

The waveguide must be pressurized at 14.7 psia, minimum, to prevent breakdown under matched conditions, VSW R = 1.1

maximum. Under mismatch conditions, VSW R = 1.5 maximum, the waveguide must be pressurized at 35 psia, minimum.

8

Unless otherwise specified for a particular test parameter (see testing program table herein), the cooling and pressurization

requirements-data indicated herein shall be effective wherever applicable throughout the testing program.

The tube shall be mounted with the cathode vertical to within 15° deviation.

9

10

Output window shall be pressurized at 14.7 psia.

11

During handling, transportation, mounting, and use, care must be exercised to prevent demagnetization. Ferromagnetic materials

should not be brought within 8 inches of the tube magnet, except at the ends where the clearance may be 3 inches. Energized

magnets must not at any time be permitted to be closer than 12 inches from the tube magnet.

12

Care should be exercised during all handling for installation, storage, and use of the tube, to prevent greater shock or vibration than

that of the values for which the tube is designed.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business