MIL-PRF-1/36J

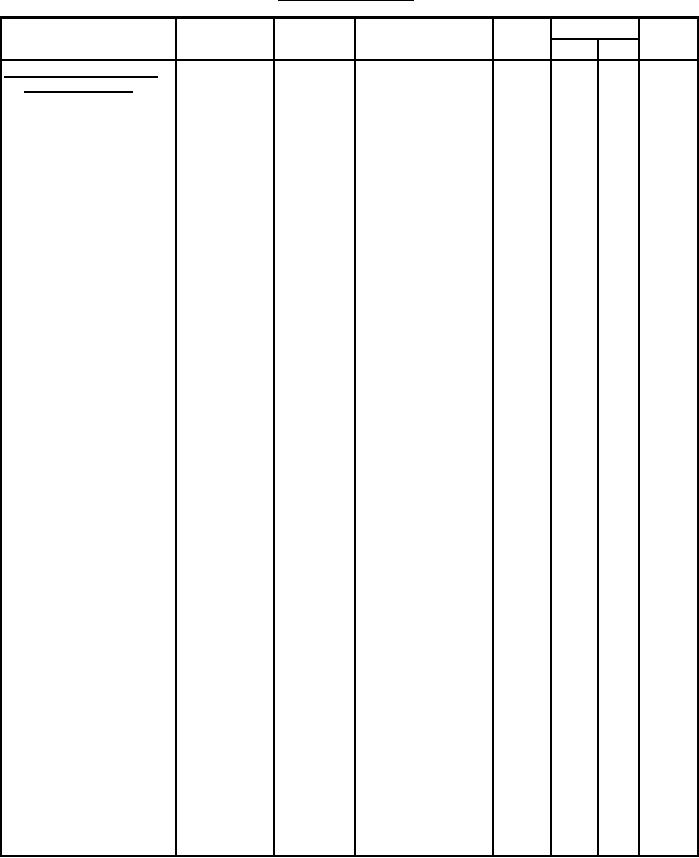

TABLE I. Testing and Inspection -Continued.

Limits

MIL-STD-1311

Requirement or test

Unit

Type

Conditions

Symbol

method

Min

Max

Conformance inspection,

part 2 continued

Angle between traces

5101

All

---

---

---

---

Neck and base alignment

5101

All

---

---

---

---

(electrostatic types)

Stray light emission

5216

All

Eb2 = 2,200 V dc;

---

---

---

---

(conventional types)

Eb3 = 4,400 V dc

Screens

5221

P2

D1(1)

360

---

cB

P7

D1(5)

400

---

cB

G5 : 1

4

---

cbf

P12

D0.1 (E)

550

---

---

D0.3 (E)

80

100

cB

P1, P2, P11 Ib3 = 100 µA dc

Line width "A"

5226

Width

---

0.75

mm

(electrostatic deflection)

(see note 6)

Ib3 = 200 µA dc

P7

Width

---

0.80

mm

(see note 6)

Ib3 = 5 µA dc

P12

Width

---

0.35

mm

(see notes 1 and 6)

P1, P2, P11 Ib3 = 100 µA dc

Line width "B"

5226

Width

---

0.90

mm

(electrostatic deflection)

(see note 8)

Ib3 = 200 µA dc

P7

Width

---

1.00

mm

(see note 8)

Ib3 = 5 µA dc

P12

Width

---

0.40

mm

(see notes 1 and 8)

Focusing-voltage at cutoff

5246

P1, P2,P11

Eb1

345

515

V dc

P7

Eb1

460

690

V dc

P12

Eb1

345

517

V dc

Deflection factor (1D2)

5248

P1, P2,

DF

127

173

V dc/in.

P11,P12

P7

DF

170

230

V dc/in.

Deflection factor (3D4)

5248

P1, P2,

DF

94

128

V dc/in.

P11,P12

P7

DF

125

170

V dc/in

Heater-cathode leakage

5251

All

---

---

---

---

current

Secureness of base, cap, or

1101

Al

---

---

---

---

insert

Permanence of marking

1105

---

---

---

---

Base pin solder depth

1111

---

---

---

---

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business