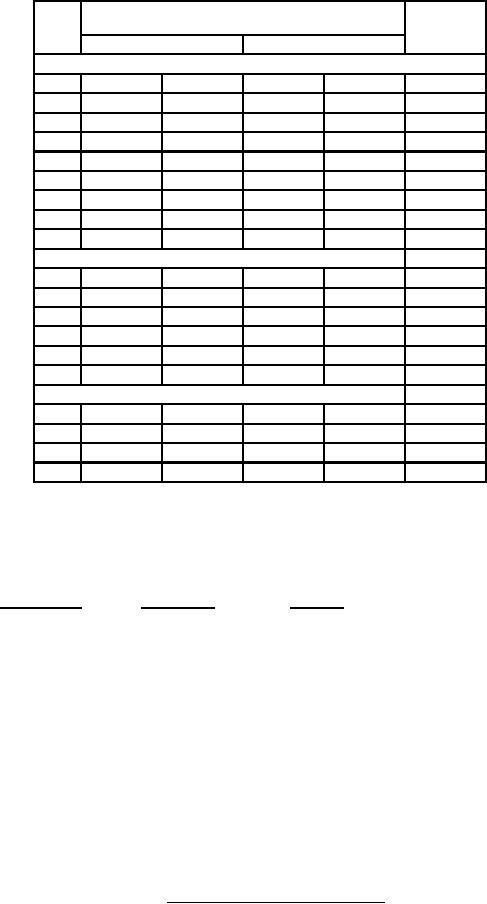

MIL-PRF-1/1766B

Dimensions

Notes

LTR

Millimeters

Inches

Conformance inspection, part 2

Min

Max

Min

Max

A

25.15

25.65

0.990

1.010

2

C

18.80

19.05

0.740

0.750

2

D

1.19

1.35

0.047

0.053

2

E

5.00

5.26

0.197

0.207

2

F

34.80

36.32

1.370

1.430

G

29.21

30.61

1.150

1.205

K

9.27

11.05

0.365

0.435

L

19.05

21.59

0.750

0.850

Conformance inspection, part 3

1

B

16.26

16.76

0.640

0.660

H

17.14

19.68

0.675

0.775

J

3.18

4.95

0.125

0.195

M

1.02

1.90

0.040

0.075

N

5.08

6.86

0.200

0.270

P

0.18

0.33

0.007

0.013

Electrode contact dimensions

5

AA

2.03

----

0.080

----

3, 4

AB

6.98

9.14

0.275

0.360

3, 4

AC

31.24

34.04

1.230

1.340

4

AD

24.89

27.94

0.980

1.100

4

NOTES:

1. Use a sample of 4.

2. Gold plate (note a applies).

3. Eccentricity of contact surfaces shall be gaged from the center line of reference and shall be as follows (note a applies):

Contact surface

TIR maximum

Reference

Anode (A)

0.040 (1.02)

Cathode (E)

Grid (C)

0.020 (0.51)

Cathode (E)

4. Dimensions of contact surfaces shall apply throughout entire contact area.

5. Dimensions in electrode contact area table are for conformance inspection, part 2 purposes only, and are not intended for inspection

purposes.

6. This surface shall not be used for clamping or locating.

7. Eccentricity of backup ceramic to anode (A) 0.031 (0.79 mm) maximum; to be measured with EIMAC gage G-2285, or equivalent.

FIGURE 1. Outline drawing of electron tube type 8980 - Continued.

5