MIL-PRF-1/1729E

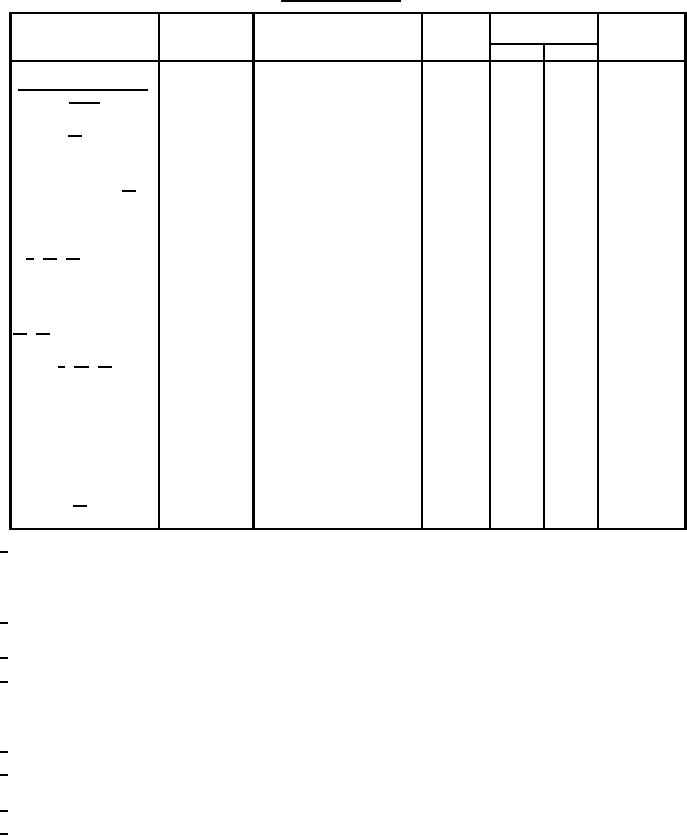

TABLE I. Testing and inspection - Continued.

Inspection

MIL-STD-1311

Conditions

Symbol

Limits

Unit

method

Min

Max

Conformance inspection,

part 3

Group C; Ef = 6.3 ±0.1 V;

Life test

10/

---

---

---

---

---

heater standby; t = 500 hours

Ćib

Life-test end point: 10/

---

---

25

%

ĆCgp

---

0.15

pF

F = 55 to 500 Hz;

Sweep-frequency vibration

---

Ep

---

250

mV ac

accel = 10 G (peak);

8/ 12/ 13/

Ebb = 400 V dc;

Rp = 10,000 ohms,

Ec/Ib = 10 mA

Condition A; no voltages

Shock, specified pulse

1042

---

---

---

---

13/ 14/

No voltages applied

Torque 8/ 13/ 18/

---

---

---

---

---

Shock and torque -

---

test end point:

µA dc

Ic

---

-10

Total grid current

1266

Pressure = 35 mmHg (max);

Barometric pressure,

1002

---

---

---

---

voltage = 2.0 kV ac

reduced 15/

1/

The transit-time heating effect of the cathode may require compensation by a reduction in heater voltage after dynamic

operation of the tubes has started. The back heating is a function of frequency, grid current, grid bias, anode current, duty

cycle, and circuit design and adjustment. There is an optimum heater voltage which will maintain the cathode at the correct

operating temperature for a particular set of operating conditions. A maximum variation of ±5 percent from optimum is

permitted. No reduction in heater voltage is required up to and including 500 MHz.

2/

The regulation or series-anode-supply impedance, or both, shall limit the instantaneous peak current, with the tube

considered as a short circuit, to a maximum of 10 times the specified maximum current rating.

3/

The maximum instantaneous peak grid-cathode voltage shall be within the range of +175 to -750 volts.

4/

Sufficient conduction, convection, and force-air cooling shall be provided to limit the envelope and anode shank temperatures

to the specified maximum value under all operating conditions. Reliability will be seriously impaired if this maximum is

exceeded. Where emphasis is placed on long and reliable life, lower temperatures shall be used. To insure proper cooling,

the tube shall be sufficiently tightened into the heat sink (15 to 20 inch-pounds). The maximum torque, however, shall not

exceed 20 inch-pounds.

5/

Operation at this altitude is possible in a suitably designed circuit.

6/

Sufficient conduction, convection, and forced-air cooling may be used in all electrical tests involving application of heater

voltage to maintain the anode shank and seal temperatures within the specified maximum values.

7/

All tests listed under conformance inspection, part 1, shall be performed at the conclusion of the holding period.

8/

Other tube contact configurations may be used provided the tube contact area remains unchanged and the socket, jig, or

cavity gives equal performance. Mounting of the socket, jig, or cavity may be at the option of the manufacturer.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business