MIL-PRF-1/1717C

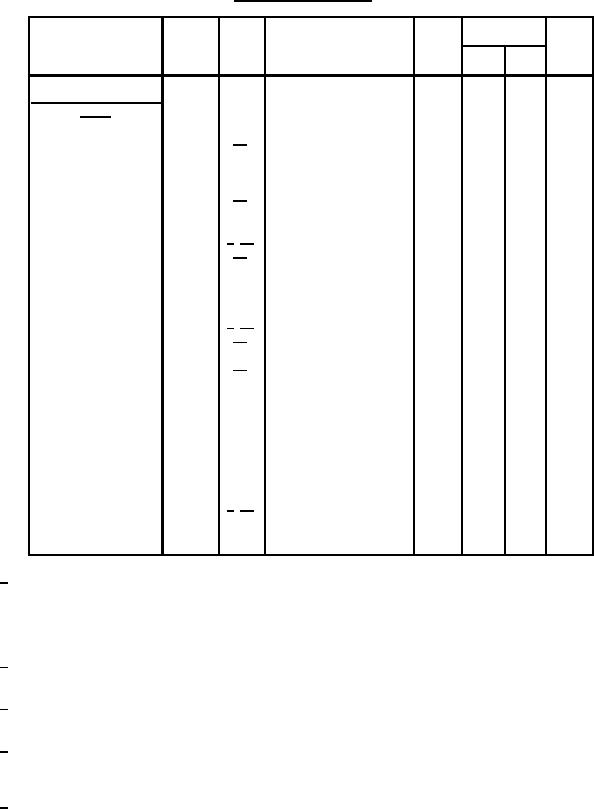

TABLE I. Testing and inspection - Continued.

Inspection

Method

Notes

Conditions

Symbol

Limits

Unit

Min

Max

Conformance inspection,

part 3

---

---

---

---

Group C;

16/

Ef = 6.0 V;

---

Life test

filament standby;

t = 500 hours

---

25

%

Life-test end point

---

16/

Ćib

---

0.15

pF

ĆCgp

Variable-frequency

---

9/ 11/ F = 55 to 500 to 55 Hz;

Ep

---

250

mV ac

vibration

14/ Accel = 10 G peak (min);

Ebb = 300 V dc;

Rp = 10,000 ohms;

Ec/Ib = 10 mA dc

Torque

---

9/ 11/ No voltages applied

---

---

---

---

15/

Shock, specified pulse

1042

11/

Condition A;

---

---

---

---

no voltage applied;

fixture in accordance with

Drawing 280-JAN

---

Torque and shock-test

end point:

Total grid current

1266

---

Ic

---

-10

µA dc

---

---

---

---

8/ 11/ Pressure = 35 mmHg (max);

1002

Barometric pressure,

voltage = 2,000

reduced

V ac; TA = 30°C ± 10°C

1/ The transmit-time heating effect of the cathode shall be compensated for by a reduction in heater voltage after

dynamic operation of the tube has started. The back heating is a function of frequency, grid current, grid bias, anode

current, duty cycle, and circuit design and adjustment. There is an optimum heater voltage which will maintain the

cathode at the correct operating temperature for a particular set of operating conditions. A maximum variation of ± 5

percent from optimum is permitted. No reduction in heater voltage is required up to and including 500 MHz.

2/ The regulation, or series anode supply impedance, or both, shall limit the instantaneous peak current, with the tube

considered as a short circuit, to a maximum of 10 times the specified maximum current rating.

3/ The maximum instantaneous peak grid voltage for grid-pulse conditions shall be within the range of

+250 to -750 volts.

4/ Sufficient conduction and convection cooling shall be provided to limit the envelope and anode shank temperatures to

the specified maximum value under all operating conditions. Reliability will be seriously impaired if this maximum is

exceeded. W here emphasis is placed on long and reliable life, lower temperatures should be maintained.

5/ Sufficient cooling shall be provided for all seals to limit temperature in accordance with 4/. In cases where long life

and consistent performance are factors, cooling in excess of minimum requirements is normally beneficial.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business