MIL-PRF-1/1669A(CR)

TABLE I. Testing and inspection - Continued.

1/

Refer to MIL-PRF-1, section 3.4.5, "Absolute ratings".

2/

At any ambient temperature, particular care must be taken (see 4/) to maintain the collector, body, and tuner fins below their

maximum rated operating temperatures.

The cooling requirements specified or otherwise covered herein (see 4/) shall be effective wherever applicable throughout the

3/

testing program herein. The collector temperature shall be measured on the top surface of the collector and the tuner fin

temperature shall be measured near the fin shaft. (The thermostat on the collector should be used in an interlock circuit that will

remove the beam voltage if the collector temperature becomes abnormally high. This normally closed, Klixon 11041-106-1 or

equivalent, thermostat has a switch rating of 50 V dc at 2 amps, or 120 V ac at 1 amp; it opens at 265.6 10 C (510 F 18 F),

and closes at 237.8 C 10 C (460 F 18 F)).

4/

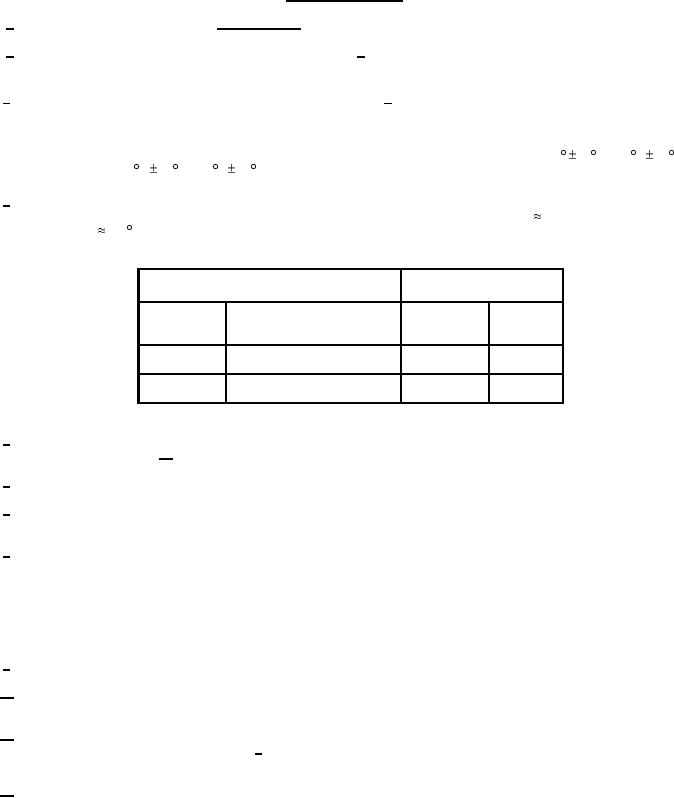

Relative to the tube temperature-control requirements specified herein, the following cooling-means accomplishment is

recommended. The listed values are approximate, and apply to conditions: sea-level air pressure 760 mmHg, normal ambient

temperature +20 C.

Air flow

Inlet air pressure

Collector

Body (including tuner fins)

Collector

Body

(ducted)

(ducted)

Inch-H2O

Inch-H2O

Pound/hour

Pound/hour

815

270

2.0

0.75

5/

The tube may be operated in any position, but the preferred (particularly for fixed-installation operation) mounting position is vertical,

cathode end down (see 11/).

6/

Ferromagnetic material shall not be brought within 6 inches of the tube; other magnets, not closer than 12 inches.

7/

Care should be exercised during all handling for installation, storage, and use of the tube, to prevent shock or vibration in excess of

the values for which the tube is designed.

8/

The preproduction sample approval requirements in U.S. Army Electronics Command drawing SC-A-46600B hereby replace any

qualification requirements referable to the product covered herein. However, the requirements of paragraphs 3.1.2.1, 3.1.2.2,

3.1.3, and 4.4 in drawing SC-A-46600B shall be considered not applicable to the product covered herein.

(Copies of U.S. Army Electronics Command drawing SC-A-46600B, 19 March 1965, "Preproduction Sample Approval In Lieu Of

Qualification Requirements In Specifications For Semiconductor Devices And Electron Tubes" may be obtained from the acquiring

activity or as directed by the contracting officer.)

9/

A production lot is defined as two (2) months production or seventy (70) tubes, whichever is less.

10/

Tube-designation marking shall be in accordance with MIL-PRF-1. If any specification-requirements waiver has been granted, the

product-identification marking shall consist of the tube type-number only.

11/

Tube identification and tube serial number shall be marked in the most practical and most readily discernible location on the tube,

relative to its normal mounted position (see 5/). Also, indication of the sequential alignment of the tuning cavities shall be effected

by marking, equivalent to that shown in figure 1.

12/

Although all tests covered herein are required to be performed during preproduction sample approval inspection, the two tests listed

under this caption are performed, normally, during preproduction sample approval only. A failure of any one tube in any of the

these tests shall be cause for preproduction-sample disapproval.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business