MIL-PRF-1/1669A(CR)

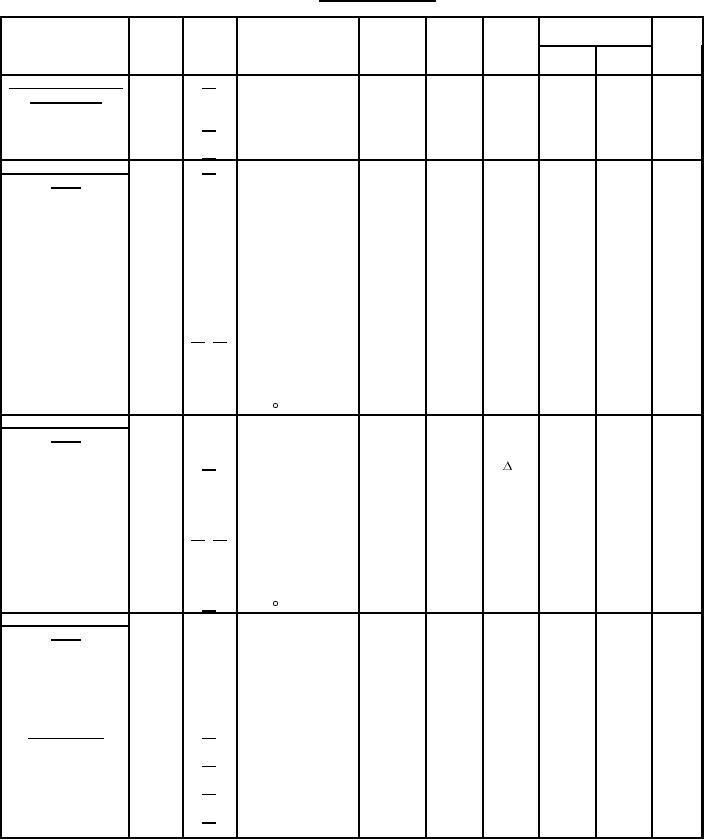

TABLE I. Testing and inspection.

Inspection

Method

Notes

Conditions

Acceptance Inspection Symbol

Limits

Unit

level

level or

code

Min

Max

Preproduction sample

12/

approval tests

Humidity

---

13/

---

---

---

---

---

---

Tunable frequency

---

14/

F = 4400 to 5000 MHz

---

---

---

---

14

turns

15/

Conformance inspection,

part 1

Visual-mechanical

---

---

See figure 1

---

---

---

---

---

---

examination

Heater current

1301

---

0.65

S3

If

7.4

8.2

A

Cathode current

1256

---

0.65

S3

Ik

450

520

mA dc

Body current

1256

---

Power output (2)

0.65

S3

Iby

---

35

mA dc

0.65

S3

Po

1.2

---

kW

Power output (2)

4250

16/ 17/ Tuned for high

Po/Pi

32

---

%

efficiency; F = 4400,

4700, and 5000 MHz;

Pd = 50 mW

Tuner starting torque

4223

---

0.65

S3

---

---

30

oz.-in.

t = +20 C, approx.

Conformance inspection,

part 2

2.5

S1

Bandwidth

4271

18/

-3 db (power level at

7

---

MHz

F

band limits); Power

output (2) conditions

except F = 4700 MHz

6.5

S1

Po

1.0

---

KW

Power output (1)

4250

16/ 17/ Tuned for high gain;

F = 4400, 4700, and

5000 MHz; Pd = 50

mW

6.5

S1

---

---

200

oz.-in.

Tuner stop torque

---

19/

t = +20 C, approx.

Conformance inspection,

part 3

Life test

---

---

Group D; Power output

---

---

t

1000

---

hrs

(2)

Life test end-points:

---

---

Power output (2)

---

---

Po

1.0

---

kW

`

Periodic check

20/

Shock

1042

21/

No voltages

---

---

---

---

---

---

Vibration

---

22/

No voltages

---

---

---

---

---

---

Mechanical tuning

---

23/

---

---

---

100

---

cycles

fatigue

See footnotes at top of next page.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business