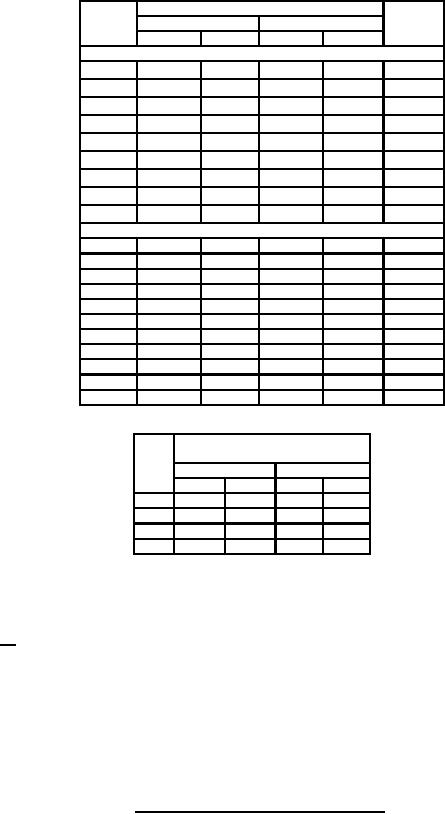

MIL-PRF-1/1660C

Dimensions

Ltr

Inches

Millimeters

Notes

Min

Max

Min

Max

Conformance inspection, part 2

A

1.500

1.560

38.10

39.62

B

---

1.214

---

30.84

D

1.125

1.165

28.58

29.59

F

.800

.840

20.32

21.34

G

.462

.477

11.73

12.12

N

1.025

1.035

26.04

26.29

2

R

.655

.665

16.64

16.89

2

T

.213

.223

5.41

5.66

U

.315

.325

8.00

8.26

3

Conformance inspection, part 3 (see note 1)

C

.125

.185

3.18

4.70

H

---

.040

---

1.02

J

.766

.826

19.46

20.98

K

.025

.046

0.64

1.17

L

1.234

1.264

31.34

32.11

M

1.180

1.195

29.97

30.35

P

.752

.792

19.10

20.12

V

---

.086

---

2.18

W

---

.100

---

2.54

Y

.105

.145

2.67

3.68

Z

.650

.850

16.51

21.59

Dimensions for electrode

Ltr

contact surfaces

Inches

Millimeters

Min

Max

Min

Max

AA

.035

.361

0.89

9.17

AB

1.021

1.101

25.93

27.97

AC

1.219

1.413

30.96

35.89

AD

1.160

1.500

29.46

38.10

NOTES:

1.

Dimensions shall be checked during the initial production and annually thereafter. An accept on zero defect

sampling plan shall be used, with sample size of three tubes, and with an acceptance number of zero failures.

In the event of failure, the test will be made as a part of conformance inspection, part 2, acceptance level 6.5

(see 21/). Annual sampling plan shall be reinstated after three consecutive samples have been accepted.

2.

The total indicated runout of the anode and grid contact surfaces with respect to the cathode contact surface

will not exceed .020 inch (0.51 mm).

3.

Tht total indicated runout of the cathode contact surface with respect to the heater contact surface will not

exceed .012 inch (0.30 mm).

4.

-X, +Y, +Z, -Z indicate direction of the applied shock and vibration in relation to the tube configuration.

FIGURE 1. Outline drawing of electron tube type 8403 - Continued.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business