MIL-PRF-1/1609C

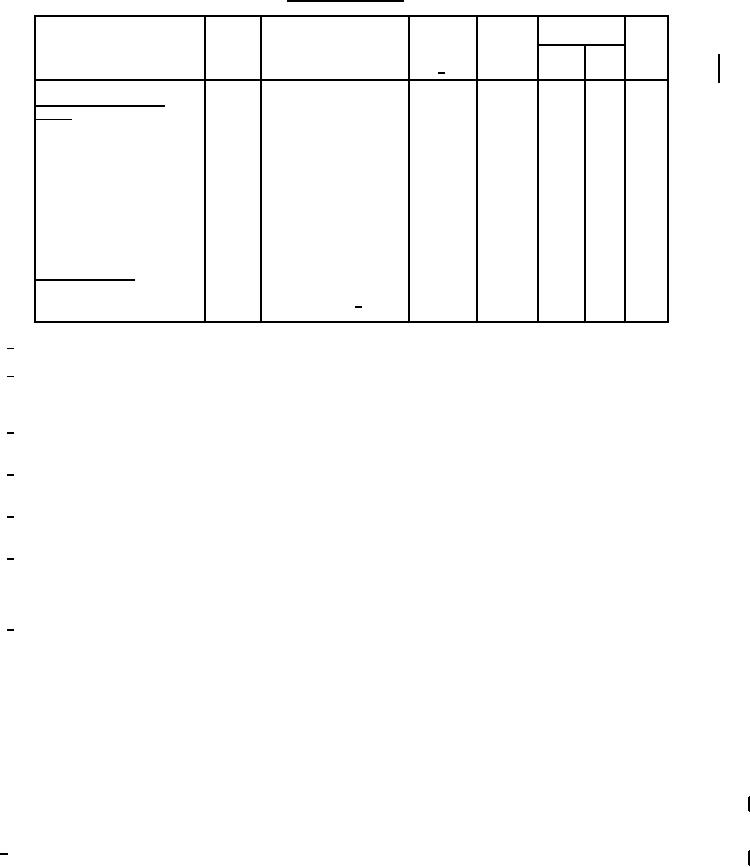

TABLE I. Testing and inspection - Continued.

Inspection

Method

Conditions

Acceptance

Symbol

Limits

Unit

MIL-STD-

Level

1311

8/

Min

Max

Conformance inspection,

part 3

---

---

---

---

---

---

Life-test provisions

Group B; Ebb/Ib = 100 ± 2

µA dc; t = 1,000 hours

---

Life-test end points:

1,550

1,645

---

Eb

3337

Voltage drop

V dc

---

---

3335

47

Regulation

ĆEb

V dc

---

---

3347

1,760

Ionization voltage

Ez

V dc

Periodic-check test

Shock specified pulse

Test condition C 2/

---

1042

---

---

---

---

1/

Criterion for passing this test shall be compliance after test with the initial requirements for voltage drop and regulation.

2/

Electrical samples shall not be used for this test. Ten additional samples shall be submitted for shock test only. Criterion for

passing this test shall be compliance after test of at least 80 percent of the tubes with the initial requirements of voltage drop and

regulation.

3/

The tube under test shall not have been conducting for at least 30 minutes prior to test. During this test, the regulator tube shall

not be exposed to external sources of radiation and shall be shielded from light. No conditioning current is permitted.

4/

Eb maximum shall not be exceeded anywhere within the regulated current range. In testing for regulation, current shall be varied

continuously through the regulated range.

5/

Peak current is the current maximum during a transient pulse which will not cause damage to the tube or cause tube to go into

glow.

6/

The holding period commences upon completion of the initial performance of the indicated tests. At the conclusion of the holding

period, the indicated tests will be performed again. Of the tubes failing the holding-period end-point test, those which fail with

respect to voltage drop only, may be retested after an additional 60-day period. ĆEb(1) is the change in voltage drop from

beginning to end of holding period.

7/

First article testing requirements hereby replace any qualification requirements referable to the product covered herein. The term

"First article testing" shall be considered as synonymous with the term "Preproduction sample approval testing." All tests

applicable herein (including all first article tests and conformance inspection, parts 1, 2, and 3) shall be performed during first

article testing. A failure of any one tube in any of the tests shall be cause for decision of first article sample disapproval. The

contractor/manufacturer shall provide test reports and written assurance that:

(a) The first article sample is representative of the product to be submitted under the contract.

(b) First articles shall be manufactured from new materials and in the facility that produced the sample tubes.

A test plan shall be submitted to the contracting officer for approval prior to proceeding with first article testing. The test plan shall

list all production test and laboratory test facilities to be utilized in first article testing and production phases of the contract. Upon

receipt of approval of the test plan, first article testing may proceed. W hen testing has been completed, three copies of the test

report shall be prepared(see MIL-HDBK-831 for guidance), certified by a government representative and submitted with the test

samples to the contracting officer for approval.

8/

This specification sheet uses accept on zero defect sampling in accordance with MIL-PRF-1, table III.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business