MIL-PRF-1/1424C

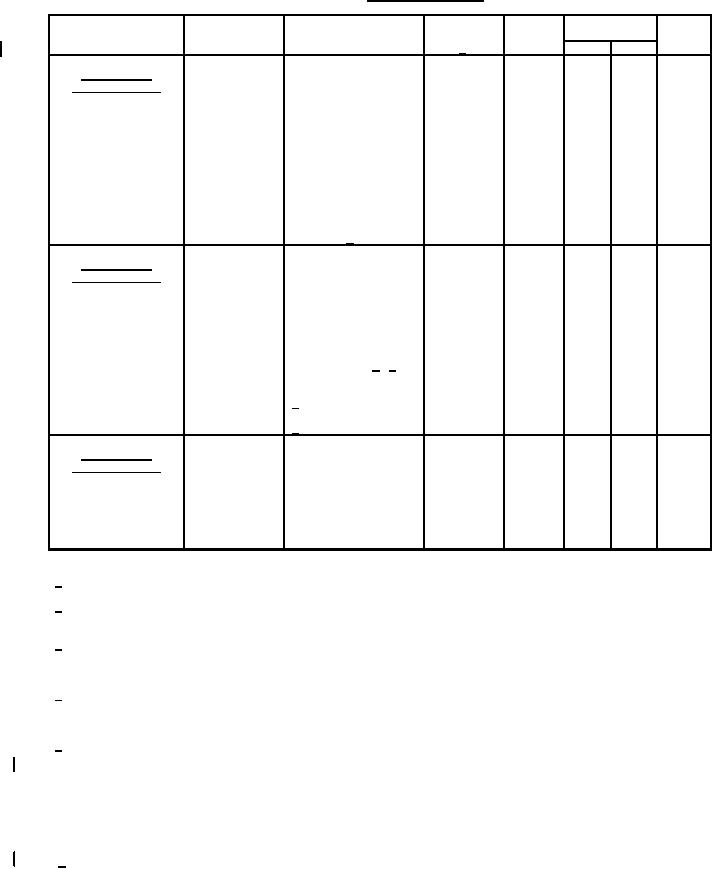

TABLE I. Testing and inspection.

Acceptance

Inspection

Method

Condition

Level

Symbol

Limits

Unit

MIL-STD-1311

6/

Min

Max

Conformance

inspection, part 1

Peak emission

1231

eb = 8.0 kv;

0.65

is

30

---

a

Ef = 12.2 V ac

Electrode current

1256

Eb = 500 V dc

0.65

Ib

750

---

mA dc

(anode)

Filament current

1301

0.65

If

14.00

16.25

A ac

Operation of

1353

epx = 40 kv;

0.65

---

---

---

---

rectifiers (1)

Ib = 700 mA dc;

ib = 2.5 a 1/

Conformance

inspection, part 2

Low-frequency

1031

No voltage

6.5

---

---

---

---

vibration

Shock test

1041

300 G

6.5

---

---

---

---

Operation of

---

Ef = 12.2 V ac 1/ 2/

6.5

---

---

---

---

rectifiers (2)

Slap on voltage

---

3/

---

---

---

---

---

Crowbar test

---

4/

---

---

---

---

---

Conformance

inspection, part 3

Life test

---

Group D; operation of

---

t

500

---

hr

rectifiers (1)

Life-test end point

---

Peak emission

---

is

20

---

a

1/ The tube shall operate for 2 minutes without arcing or sign of gas during a test interval not to exceed 5 minutes.

2/ The tube shall be operated as a shunt diode in a thyratron modulator. The circuit constants shall be chosen to give the following

diode operating conditions: epx = 33 kv; ib = 50 a; and effective current (Ieff) = 1.25 A ac.

3/ A slap-on voltage shall be applied to the tube under the following load condition: epx = 30 kv; Ib = 700 mA dc; ib = 6.0 a minimum

for a minimum duration of 16 milliseconds. The slap-on voltage shall be applied as often as necessary during a test interval not to

exceed 5 minutes until the tube hold-off is five times without kicking out the overcurrent relay.

4/ W hile operating at full load as a rectifier under the following conditions, epx = 40 kv; Ib = 700 mA dc; ib = 2.5 a, the tube shall be

subjected to a simulated crowbar test by drawing a 12.5 a short 20 times. These crowbars shall not result in damage to the cathode

coating. Minimum of crowbar shall be 32 milliseconds. Following this test the tube shall meet operation (1) requirements.

5/ First article inspection shall consist of performing all tests listed on this tube specification sheet. The sample size and allowable

defects shall be in accordance with MIL-PRF-1. Three copies of the test report shall be forwarded to the purchasing activity for

evaluation by the preparing activitiy.

Invitation for bids should provide that the preparing activity reserves the right to waive the requirements for first article samples as to

those bidders offering a product which has been previously acquired or tested by the Government, and that bidders offering such

products who wish to rely on such production or test, must furnish evidence with the bid that prior Government approval is presently

appropriate for the pending acquisition.

6/ This specification sheet uses accept on zero defect sampling in accordance with MIL-PRF-1, table III.

2