MIL-PRF-1/1392D

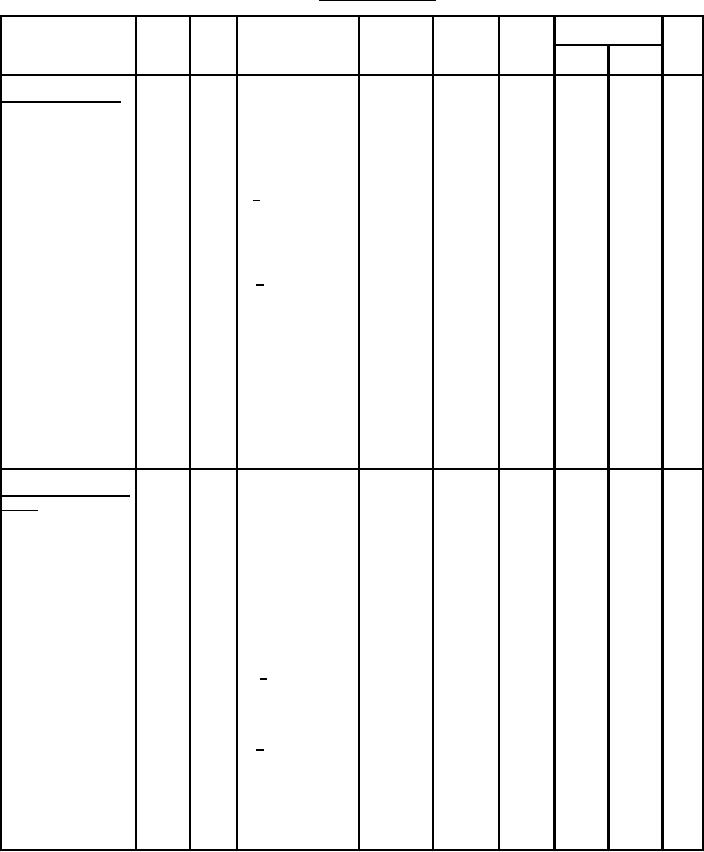

TABLE I. Testing and inspection.

Inspection

Inspection

Method

Type

Conditions

Acceptance

level

Symbol

Limits

Unit

level

or code

Min

Max

Qualification inspection

Pressure (implosion)

1141

All

---

---

---

---

---

---

Barometric pressure,

1002

All

Pressure = 54 mmHg

---

---

---

---

---

---

reduced

Vibration

5111

All

4/

---

---

Width

---

2.0

mm

Direct-interelectrode

1331

All

k to all

---

---

Ck

---

10.0

pF

capacitance

g1 to all

---

---

Cg1

---

11.0

pF

g2 to all

---

---

Cg2

---

12.0

pF

Blue/orange light ratio

---

P14A

5/

---

---

Ratio

1.0

1.5

---

µA dc

Electrode currents

5201

All

Ec1 = 0

---

---

Ic2

---

50

(grid No. 2)

Face tilt

5101

All

---

---

---

---

---

---

Neck and bulb alignment

5101

All

---

---

---

---

---

---

(magnetic types)

Cathode illumination

5216

All

---

---

---

---

---

---

Base material insulating

1216

All

---

---

---

---

---

---

quality

Conformance inspection,

part 1

Bulb, screen, and

5106

All

---

---

---

---

---

---

faceplate quality

Voltage breakdown

5201

All

---

---

---

---

---

---

Voltage breakdown

5201

All

---

---

---

---

---

---

(magnetic types)

Ib = 200 µA dc

ĆEc1

Modulation

5223

All

---

---

---

38

V dc

Gas ratio

5206

All

3/

---

---

Gr

---

0.25

---

Neck straightness

5101

All

---

---

---

---

---

---

P7A Ib = 50 µA dc

Neck shadow

---

---

---

---

3.82

---

inch

P14A

7/

Spot position

5231

All

---

---

---

---

9.0

mm

(magnetic deflection)

Zero-bias anode current

5236

All

---

---

---

---

---

---

(magnetic deflection)

See footnotes at end of table.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business