MIL-PRF-1/1371J

Dimensions

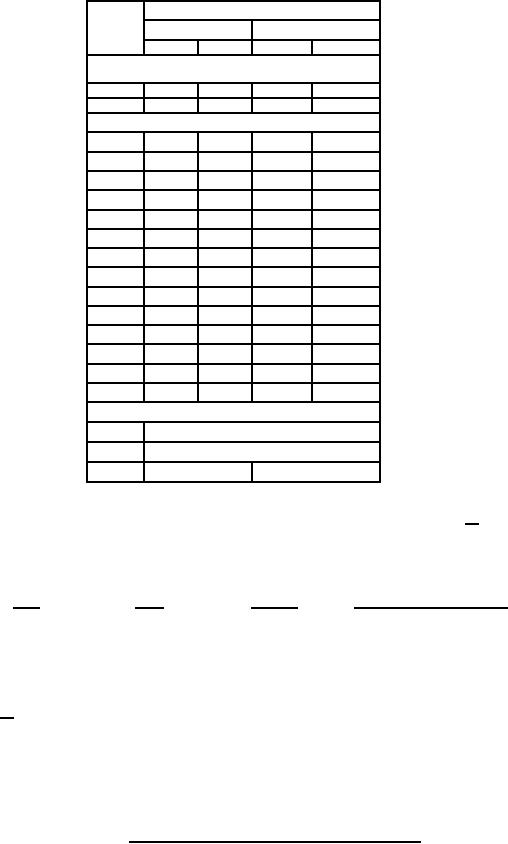

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 1

(see note 1)

K

.100

.180

2.54

4.57

N

2.985

3.015

75.82

76.58

Conformance inspection, part 2

A

---

5.895

---

149.73

B

3.945

4.340

100.20

110.24

C

---

1.555

---

39.50

D

2.985

3.015

75.82

76.58

E

2.410

2.530

61.21

64.26

F

---

.313

---

7.95

G

.980

1.355

24.89

34.42

H

.093

---

2.36

---

J

.520

.570

13.21

14.48

M

---

.375

---

9.53

P

3.235

3.265

82.17

82.93

R

3.245

3.305

82.42

83.95

S

---

1.081

---

27.46

W

---

.469

---

11.91

Reference dimensions

135°

T

90°

U

V

1.500

38.10

NOTES:

1. The acceptance level for dimensions listed under conformance inspection, part 1, shall be 1.0 (see 18/).

2. Reservoir and heater terminals shall be identified and marked on tube base as specified herein.

3. Insulated leads to be on 10.00 inch (254.0 mm) ± 1.00 inch (25.4 mm) centers.

4. Lead identification terminal lugs and insulation sleeving (in accordance with MIL-I-3190) shall be as follows.

See note 5 for inspection procedures.

Lead

Color

Sleeving

Terminal lugs clearance hole

H = Heater

Yellow

H-A-I or H-B-I

.25 stud

R = Reservoir

Red

H-A-I or H-B-I

#10 stud

5. Dimensions shall be checked during the initial production and once each succeeding 12-calendar months in which there is

production. An accept on zero defect sampling plan shall be used, with sample of three tubes with an acceptance number

of zero. In the event of failure, the test will be made as a part of conformance inspection, part 2, with an acceptance level

of 6.5 (see 18/). The "12-calendar month" sampling plan shall be reinstated after three consecutive samples have been

accepted.

FIGURE 1. Outline drawing of electron tube type 7322 - Continued.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business