MIL-PRF-1/1350G

Dimensions

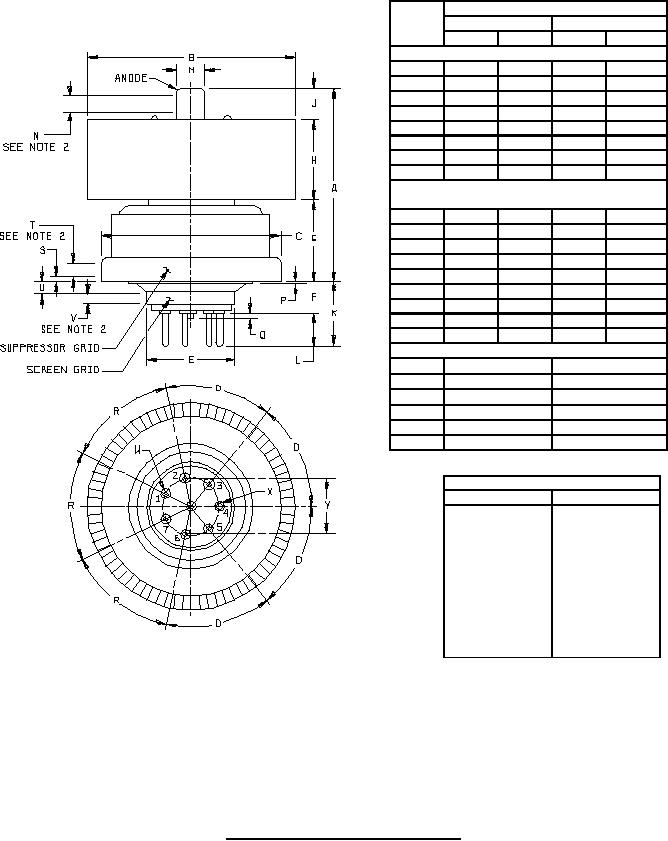

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 2

A

3.458

3.832

87.83

97.33

C

3.485

3.515

88.52

89.28

E

1.615

1.630

41.02

41.40

F

.655

.719

16.64

18.26

K

1.056

1.219

26.82

30.96

M

.559

.573

14.20

14.55

W

.056

.062

1.42

1.57

X

.120

.127

3.05

3.23

Conformance inspection, part 3

(see note 1)

B

3.968

4.032

100.79

102.41

G

1.395

1.645

35.43

41.78

H

1.468

1.532

37.29

38.91

J

.593

.657

15.06

16.69

L

.438

.562

11.13

14.27

N

.400

---

10.16

--

P

---

.125

---

3.18

T

.250

---

6.35

---

V

.220

---

5.59

---

Reference dimensions

51°

51°

D

Q

.125

3.18

52°

52°

R

S

.125

3.18

U

.250

6.35

Y

1.000

25.40

PIN CONNECTIONS

Pin No.

Element

k

1

g1

2

h

3

k

4

h

5

g1

6

k

7

int con

Center pin

g2

Lower ring

g3

Upper ring

a

Cap

NOTES:

1. Dimensions shall be checked yearly. An accept on zero defect sampling plan shall be used, with sample of three tubes

with an acceptance number of zero. In the event of failure, the test will be made as a part of conformance inspection, part

2, acceptance level of 6.5 (see 6/). The yearly sampling plan may be reinstated after three consecutive samples have been

accepted.

2. Contact surface shall be confined to this area.

FIGURE 1. Outline drawing of electron tube type 8295A.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business