MIL-PRF-1/1350G

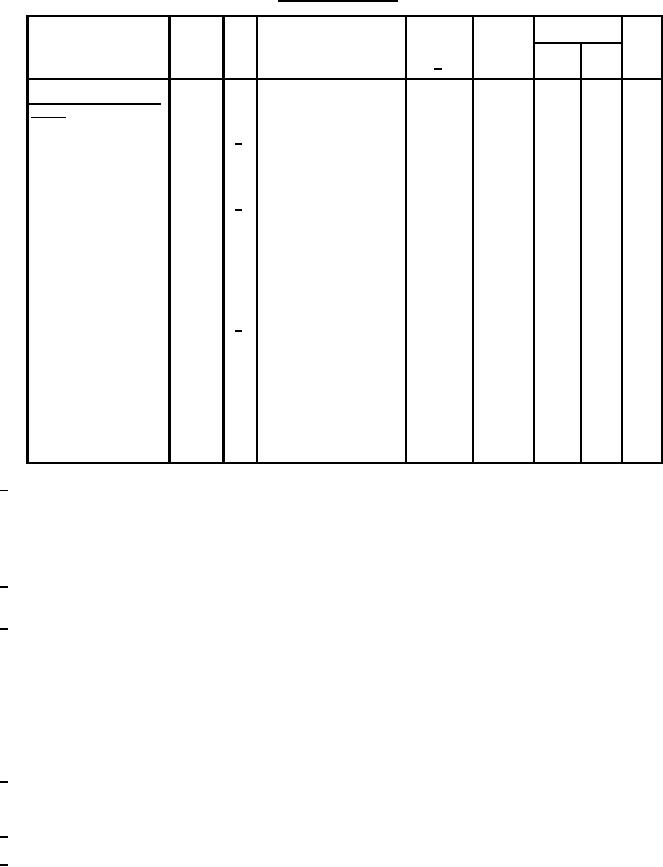

TABLE I. Testing and inspection - Continued.

Inspection

Method Notes

Conditions

Acceptance

Symbol

Limits

Unit

MIL-STD-

level

1311

6/

Min

Max

Conformance inspection,

part 3

ĆIb

3/

Stability

---

Eb = 3,000 V dc;

---

---

22

mA dc

Ec1/Ibo = 220 mA dc

t

at t = 0; Read ĆIb at

t = 180 sec

Linear amplifier power

2204

3/

Class AB1 amplifier;

---

Po

1.350

---

W

output and distortion

Eb = 3,000 V dc;

3rd IM

-20

---

dB

Ec1/Ibo = 220 mA dc;

5th IM

-30

---

dB

Eg1/Ib = 800 mA dc

(1-tone); R = 2,000

± 100 ohms; Rg = 1,000

ohms (max); anode tank Q

= 10 to 15

Life test

---

4/

Group C; linear amplifier

---

---

---

---

---

Power output and distortion

except, Eg1/Po = 1,400 W

(min) (1-tone); t = 500

hours

Life-test end points:

2204

---

Linear amplifier power

---

Po

1,250

---

W

output and distortion

3rd IM

-19

---

dB

5th IM

-29

---

dB

With an anode dissipation of 1,000 watts and an incoming air temperature of 50°C at sea level, a minimum of 24 cfm of air

1/

shall be passed through the anode cooler. In all applications, an air-system socket, such as the EIMAC SK-184 or SK-184A,

or equal, should be used. With an airflow of 24 cfm, the static pressure drop for the tube and socket is approximately 0.13

inch of water. Cooling air should be applied before or simultaneously with the application of electrode voltages, including the

heater, and may be removed simultaneously with them. In cases where long life and consistent performance are factors,

cooling in excess of minimum requirements is normally beneficial.

2/

During all electrical tests involving application of heater voltage, the use of an air-system socket is permissible, with forced-air

cooling of 24 cfm maximum for air at 25°C at sea level. Correction may be made for higher altitude or temperature.

3/

The following tests, listed under conformance inspection, part 3, shall be performed every 3 months, with sample size and

acceptance on zero defect criteria as follows:

n1 = 4

c1 = 0

In case of a failure on a stability-test sample, the lot shall be reprocessed and a new sample submitted. the linear amplifier

power output and distortion test shall be performed on the sample that is used for the stability test. In case of a failure of a

linear amplifier power output and distortion test sample, this test shall become a conformance inspection, part 2, with an

acceptance level of 6.5 (see 6/). After three consecutive successful submissions, the test may revert to the conformance

inspection, part 3 test.

This is a destructive test. All voltage and current meters shall be calibrated for ± 2 percent or better accuracy as installed in

4/

the equipment. Prior to the performance of the life test, the tube shall have met the requirements of the linear amplifier power

output and distortion test.

5/

This test is to be the first test performed at the conclusion of the holding period.

6/

This specification sheet uses accept on zero defect sampling in accordance with MIL-PRF-1, table III.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business