MIL-PRF-1/1342C

Dimensions

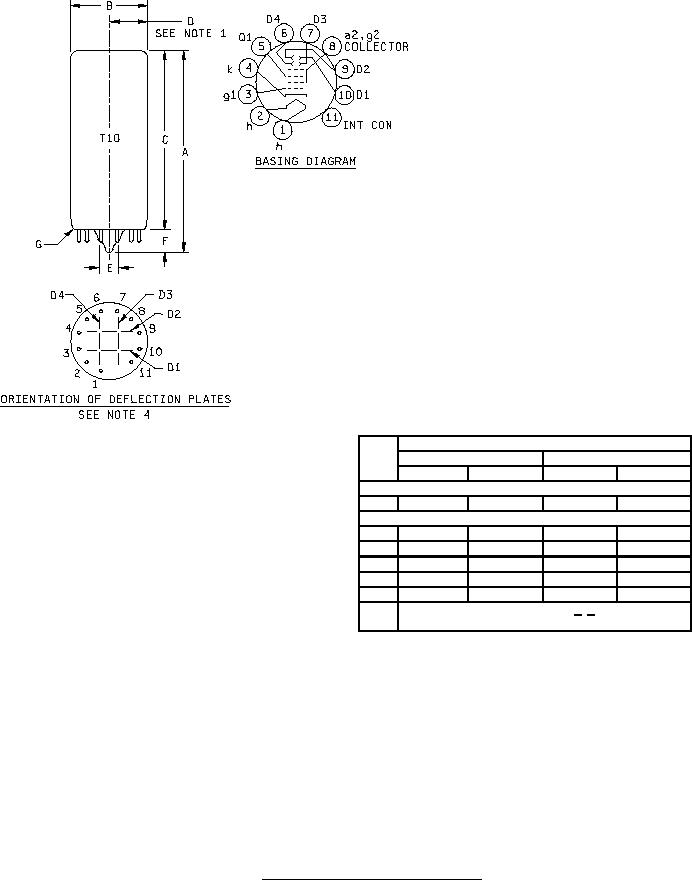

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 2

A

---

4.060

---

103.12

Conformance inspection, part 3

B

1.190 DIA

1.310 DIA

30.23 DIA

33.27 DIA

C

3.440

3.680

87.38

93.47

D

0.500 R

---

12.70 R

---

E

---

0.312 DIA

---

7.92 DIA

F

---

0.375

---

9.53

G

Base: E 11-22 2/ 3/

NOTES:

1. Useful screen radius.

2. JEDEC designation.

3. Base pin alignment shall be gauged by means of a flat-plate gauge .25 inch (6.35 mm) thick, with 12 holes .0520 ± .0005

inch (1.30 ± .01 mm) diameter and on a circle 0.6870 ± .0005 inch (17.45 ± .01 mm) diameter and 1 hole .3750 inch

(9.53 mm) diameter concentric with pin circle. Chordal distance between any two adjacent pin holes shall be .1778

± .0005 inch (4.52 ± .01 mm). Gauging procedure 1, as specified in JEDEC publication JO-G2-2, shall apply.

4. Orientation of deflection plates is shown as viewed from underside of base.

FIGURE 1. Outline drawing of electron tube type 1EP1.

4