MIL-PRF-1/1342C

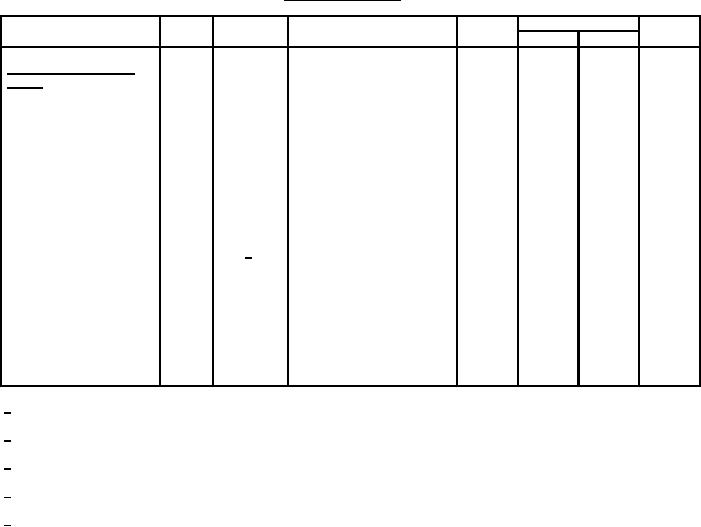

TABLE I. Testing and inspection - Continued.

Limits

Inspection

Method

Notes

Conditions

Symbol

Min

Max

Unit

Conformance inspection,

part 3

Group C; Ec1/Ik = 6 µA;

---

---

---

---

Life test

---

---

Eb2 = 1,750 V dc;

t = 500 hours (minimum)

---

Life-test end points:

Ik = 10 µA

5226

---

Width

---

0.51

mm

Line width A

Ik = 10 µA;

5226

---

Width

---

0.53

mm

Line width B

0.8 cm from center

Barometric pressure,

1002

5/

Ef = 6.3 V;

---

350

---

mmHg

reduced

Ec1 = -200 V dc;

Eb1 = 1,200 V dc;

Eb2 = 1,700 V dc;

ED1 = ED2 = ED3

= ED4 = 2,250 V dc;

Ehk = +125 V dc;

Rg1 = 1.5 Meg;

Rd = 2.0 Meg

1/ Rd is resistance of deflection plate current.

2/ This test to be performed at the conclusion of the holding period.

3/ Reject for continuous arcing.

4/ The true beam position shall fall within a circle of the indicated radius concentric with tube face.

5/

This test shall be performed during the initial production and once each succeeding 12-calendar months in which there is

production. A regular double sampling plan shall be used, with the first sample of three tubes with an acceptance number of zero,

and a second sample of three tubes with a combined acceptance number of one. In the event of failure, the test will be made as a

part of conformance inspection, part 2, code level D, with an acceptance level of 6.5. The regular "12-calendar month" double

sampling plan shall be reinstated after three consecutive samples have been accepted.

3