MIL-PRF-1/1331F

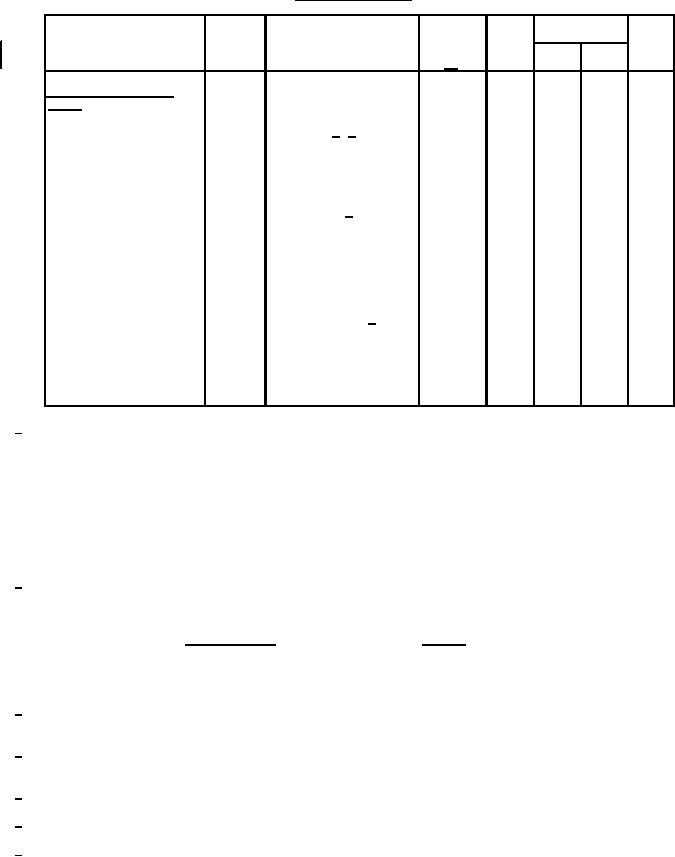

TABLE I. Testing and inspection - Continued.

Inspection

Method

Conditions

Acceptance Symbol

Limits

Unit

MIL-STD-

level

10/

Min

Max

1311

Conformance inspection,

part 3 - Continued

Inch of

1155

No voltages 4/ 9/

---

---

---

0.60

Coolant pressure drop versus

water

coolant flow (forced air)

---

---

---

---

---

Shock, specified pulse

1042

No voltages;

accel = 15G peak (min);

D = 11 ± 2 ms

half-sine wave 8/

Shock, end points:

---

Electrode voltage (grid)

1261

---

Ec1

-32

-46

V dc

Total grid current

1266

---

Ic1

---

-15

µA dc

Sweep-frequency vibration

1031

No voltages; 10 G;

---

---

---

---

---

F = 25 to 2,000 Hz 8/

Vibration end points:

---

1261

Electrode voltage (grid)

---

Ec1

-32

-46

V dc

1266

Total grid current

---

Ic1

---

-15

µA dc

1/

W hen the tube is operated at 100 percent of maximum rated anode dissipation at an incoming air temperature of 25°C maximum, a

minimum airflow of 5.6 cfm at sea level shall pass through the anode cooler. The static pressure drop across the anode cooler at

this flow is approximately 0.26 inch of water. If the socket on Drawing 246-JAN is used, an incoming airflow of 5.6 cfm to the grid

end of the socket is required. At this flow of 5.6 cfm, the static pressure drop directly across the tube and socket is approximately

0.60 inch of water. This pressure drop varies with the amount of escaping air and with the shape and construction of the air

director. The airflow rating applies at bias voltage less than 100 volts and frequencies less than 500 MHz. Air cooling of the tube

shall be increased with increased negative grid bias, increased incoming air temperature, or increased frequency of operation, or a

combination. In all cases of operation, a socket which provides forced-air cooling of the base shall be used and maximum seal and

radiator temperature ratings shall not be exceeded. The airflow shall be applied before or simultaneously with electrode voltages,

and may be removed simultaneously with them.

2/

The filament voltage is 26.5 ± 10 percent but when long life and consistent performance are factors, it is recommended that the

voltage be held at ± 5 percent. Maximum life may be obtained by adjusting the heater voltage in accordance with the application. A

table of heater voltage versus frequency is presented as a guide.

Frequency (MHz)

Ef (Vac)

Up to 300

26.5

301 to 400

25.5

401 to 500

24.3

3/

In all cases of electrical tests involving application of heater voltage, the socket on Drawing 246-JAN shall be used. An incoming

airflow of 6.0 cfm maximum to the grid end of the socket is permitted.

4/

An infinite baffle system as shown on figure 2, or equal, with an airflow of 5.6 cfm at sea level shall be used. The static pressure

drop is measured across the tube and socket.

5/

This test is to be the first test performed at the conclusion of the holding period.

6/

Circuit and cavity shall be in accordance with Drawing 223-JAN.

7/

This test shall be made a minimum of 30 minutes after Ef is turned off. Rated airflow shall be maintained during the 30-minute

interval.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business