MIL-PRF-1/1298E

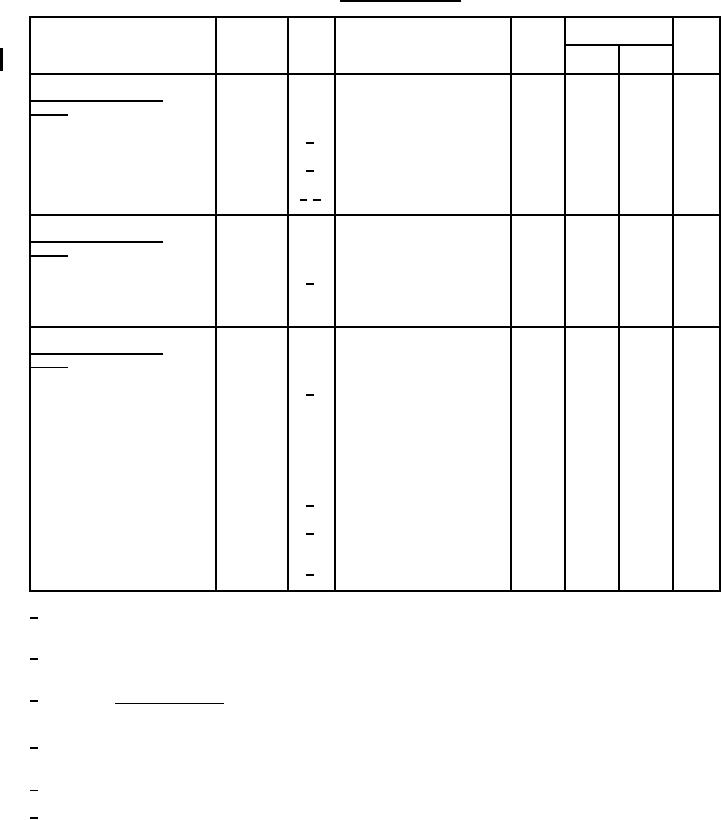

TABLE I. Testing and inspection.

Inspection

Method

Notes

Conditions

Symbol

Limits

Unit

MIL-STD-

1311

Min

Max

Conformance inspection,

part 1

µA dc

4.0

2.0

5301

Ib

Anode current

5/

µA dc

Dark current

5301

5/

Ib

---

0.00005

Gas ratio

---

3/ 5/

Gr

---

1.5

---

Conformance inspection,

part 2

Secureness of base, cap, or insert

1101

2/

---

---

---

---

Permanence of marking

1105

---

---

---

---

---

Conformance inspection,

part 3

---

Group C;

---

---

---

---

Life test

4/

Ebb = 250 V dc;

t = 500 hours (min)

Life-test end points:

---

µA dc

Anode current

5301

---

Ib

1.0

---

Low-frequency vibration (25 Hz)

1031

6/

No voltages applied

---

---

---

---

Direct-interelectrode

1331

6/

Cpk

1.6

3.0

pF

capacitance

Spectral response identification

5303

S1

---

---

---

---

6/

1/ The light during test, except in the case of life-test operating conditions, shall be incident upon a .500 inch (12.70 mm) diameter

aperture whose center is located 2.13 inches (54.10 mm) above bottom edge of base, centered with respect to axis of tube.

2/ Immersion in water shall be omitted and tubes shall be tested dry. Torque shall be applied with 20.0 pound-inch minimum for

base, 1.5 pound-inch for cap.

3/ Gas ratio = (Ib at Ebb = 250 V dc) .

(Ib at Ebb = 25 V dc)

4/ The luminous flux at the cathode shall be adjusted to give an average current of 9.0 mA on an average tube. Color

temperature shall be greater than 2,000°K.

5/ This test to be performed at the conclusion of the holding period.

6/ This test shall be performed during the initial production and once each succeeding 12-calendar months in which there is

production. A regular double sampling plan shall be used, with the first sample of three tubes with an acceptance number of

zero, and a second sample of three tubes with a combined acceptance number of one. In the event of failure, the test will be

made as a part of conformance inspection, part 2, code level D, with an acceptance level of 6.5. The regular "12-calendar

month" double sampling plan shall be reinstated after three consecutive samples have been accepted.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business