MIL-PRF-1/1260K

Pin connections

1

Grid

2

Cathode

3

Heater

4

Heater

5

Cathode

6

No connection

(do not use No. 6 pin

socket terminal as tie

point)

7

Cathode

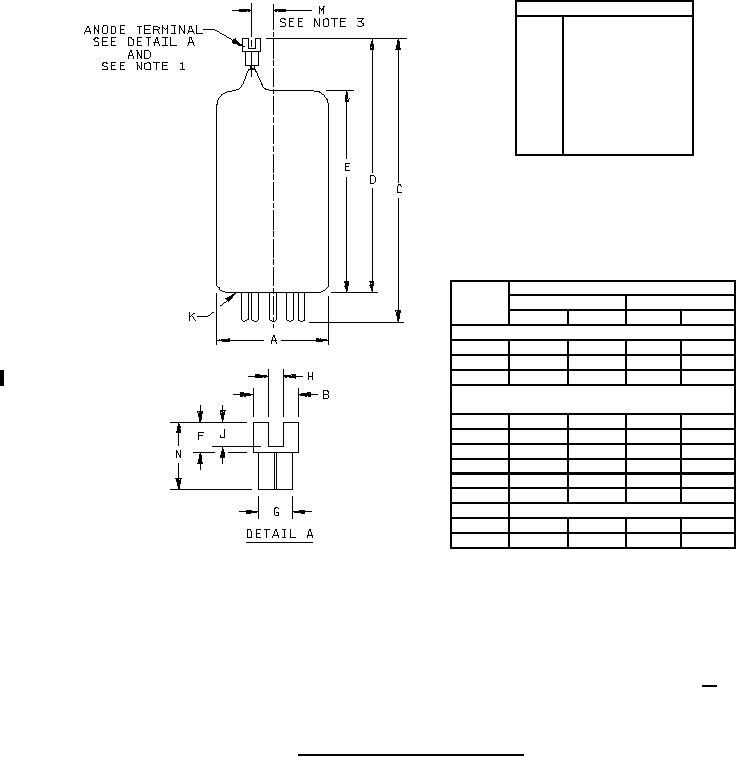

Dimensions

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 2

A

.804

.844

20.42

21.44

C

---

2.478

---

62.94

D

---

2.228

---

56.59

Conformance inspection, part 3

(see note 4)

B

.115

.135

2.92

3.43

E

---

1.593

---

40.46

F

.090

.110

2.29

2.79

G

.087

.101

2.21

2.57

H

.037

.047

0.94

1.19

J

.070

.090

1.78

2.29

K

Base: E7-1

M

.075

.175

1.91

4.45

N

.210

.230

5.33

.5.84

NOTES:

1. Anode terminal material shall be nickel.

2. Pins must be gold plated, if made of tungsten.

3. This dimension lies in a plane passing through the centerline of the tube and pin 6.

4. Dimensions shall be checked during the initial production and once each succeeding 2-calendar months in which there in

production. A sampling plan shall be used, with the first sample of three tubes with an acceptance number of zero. In the

event of failure, the test will be made as a part of conformance inspection, part 2, with an acceptance level of 6.5 (see 21/).

The regular "12-calendar months" sampling plan shall be reinstated after three consecutive samples have been accepted.

FIGURE 2. Outline drawing of electron tube type 7191.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business