MIL-PRF-1/1260K

Pin connections

1

Grid

2

Cathode

3

Heater

4

Heater

5

Cathode

6

Anode

7

Cathode

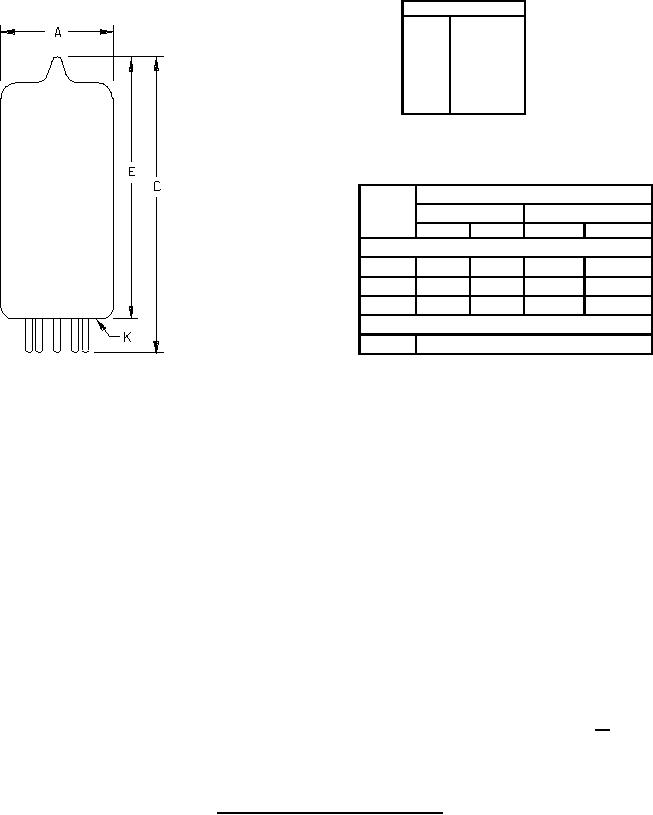

Dimensions

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 2

A

.804

.844

20.42

21.44

C

---

2.125

---

53.98

E

---

1.875

---

47.63

Conformance inspection, part 3 (see note 4)

K

Base: E7-1

NOTES:

1. Anode terminal material shall be nickel.

2. Pins must be gold plated, if made of tungsten.

3. This dimension lies in a plane passing through the centerline of the tube and pin 6.

4. Dimensions shall be checked during the initial production and once each succeeding 12-calendar months in which there in

production. A sampling plan shall be used, with sample of three tubes with an acceptance number of zero. In the event

of failure, the test will be made as a part of conformance inspection, part 2, with an acceptance level of 6.5 (see 21/). The

regular "12-calendar months" sampling plan shall be reinstated after three consecutive samples have been accepted.

FIGURE 1. Outline drawing of electron tube type 7190.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business