MIL-PRF-1/1232E

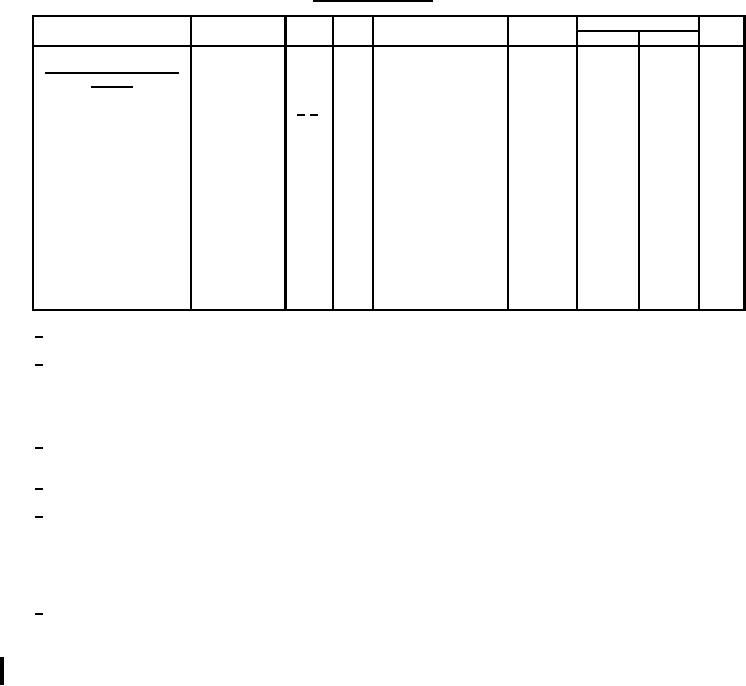

TABLE I. Testing and inspection - Continued.

Method

Limits

Inspection

MIL-STD-1311

Notes

Test

Conditions

Symbol

Min

Max

Unit

Conformance inspection,

part 3

---

2

Group D;

t

1,000

---

hours

Life test

5/ 6/

F = F3 ± 3%;

R = 2.5 Meg

Life-test end points:

---

Spike-leakage energy

4452

---

1

Ws

---

0.50

erg

Ii = 100 µA dc

Ignitor noise ratio

4460

---

---

Nr

---

1.5

---

µs

Recovery time

4471

---

2

t

---

25

Ii = 100 µA dc

Ignitor voltage drop

4406

---

---

Eid

---

550

V dc

Insertion loss

4416

---

---

Li

---

0.7

dB

Arc loss

4488

---

1

La

---

0.3

dB

Temperature cycling

1027

---

---

---

---

---

---

10 cycles

life test

1/ A suitable gasket shall be bolted between the tube and the mounting seat. Tubes shall be supplied with gaskets at both ends.

2/ Preproduction sample approval requirements hereby replace any qualification requirements referable to the product covered

herein. The term "First article testing" shall be considered as synonymous with the term "Preproduction sample approval

testing." All tests applicable herein (including all preproduction sample approval and conformance inspection, parts 1, 2, and 3)

shall be performed during preproduction sample inspection. A failure of any one tube in any of the tests shall be cause for

decision of preproduction sample disapproval.

3/ The tube shall be capable of being inserted and removed from its seat a minimum of 15 times with no deterioration in the

tube's electrical characteristics.

4/ A swept frequency method may be used for this test.

5/ The TR tube will be terminated with a waveguide to type N transition (VSWR not to exceed 1.1:1 at test frequency) and a

coaxial type N crystal mount connected to the transition. The mount will contain a type 1N21WE crystal which will be

terminated by a dc ground return of 100 ± 10 ohms. The crystal mount will have a VSWR not to exceed 1.5 when tested with a

microwave source at the test frequency which provides a crystal dc current between 0.3 ma to 1.5 ma in a 100 ohms

termination. At the beginning of life test, the crystal noise figure (NF receiver) shall not exceed 7.0 dB under the standard

1N21WE test conditions. The actual crystal noise figure at the beginning of life shall be recorded.

6/ The crystal noise figure degradation from the initial value shall not exceed 1.5 dB maximum. One crystal failure will be allowed

during the life test. If a crystal failure occurs, a new crystal shall be inserted in the mount and the life test shall continue for a

minimum of 100 hours.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business