MIL-PRF-1/1178E

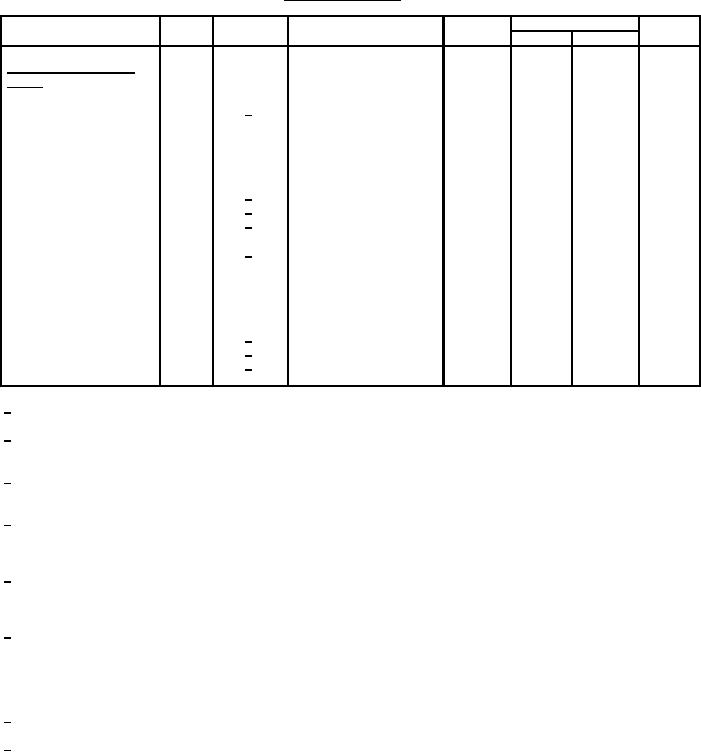

TABLE I. Testing and inspection - Continued.

Limits

Inspection

Method

Notes

Conditions

Symbol

Min

Max

Unit

Conformance inspection,

part 3

t

500

---

hours

Life test (1)

---

3/

Group C; beam current

= 2.0 µA dc; Eb2 = 10,000

V dc

Life test (1) end points:

---

Beam current = 2.0 µA dc

ĆEc1

---

Modulation

5223

22

3/

V dc

Beam current = 2.0 µA dc

---

3/

Line width "A"

5226

0.26

mm

Width

Beam current = 2.0 µA dc

3/

---

Line width "B"

5226

0.38

mm

Width

t

1,000

---

hours

Life test (2)

---

3/

Group C; beam current

= 2.0 µA dc; Eb2 = 10,000

V dc

Life-test (2) end points:

---

Beam current = 2.0 µA dc

ĆEc1

---

Modulation

44

5223

V dc

3/

Beam current = 2.0 µA dc

---

3/

Line width "A"

0.52

mm

5226

Width

Beam current = 2.0 µA dc

3/

---

Line width "B"

0.76

mm

5226

Width

1/ It is recommended that the deflection electrode circuit resistance be approximately equal.

2/ The P19 screen can be permanently damaged if the current density is permitted to rise too high. To prevent burning, minimum

beam current densities shall be employed.

3/ Beam current is measured by applying a sufficient voltage to either D1 or D2 to deflect a 1 by 1 inch (25.4 by 25.4 mm) raster until

the raster cannot be seen on the screen. Grid No. 1 bias voltage is adjusted so that either D1 or D2 will collect 2 microamperes.

4/ No dead spot of diameter greater than 1 millimeter shall be permitted within the quality area, and in any 2-inch (50.8 mm) circle

within the quality area not more than one of a diameter greater than 0.7 millimeter, and not more than four of a diameter greater than

0.3 millimeter.

5/ The ratio of the line width of a 6-inch (152.4 mm) long trace, adjusted for best center focus, to the line width measured on the

faceplate axis when the trace is deflected perpendicularly ± 3 inches (± 76.2 mm) from the face center by a balanced dc voltage,

shall be not greater than the value specified herein.

6/ With the tube enclosed in a lightproof container, with the potential specified herein applied, and with no deflecting fields applied, the

tubes shall be biased to cutoff. Under these conditions, the entire face of the tube shall be examined for stray emission by an

observer who has accommodated his eyes to viewing the face of the cathode-ray tube for at least 2 minutes through an aperture in

the lightproof container. If stray emission occurs, scanning fields such as would be required to produce a 1 by 1 inch (25.4 by 25.4

mm) raster shall be applied, under which condition, the stray emission shall disappear completely.

7/ Test shall be performed at the conclusion of the holding period.

8/ Inspection shall be 100 percent.

4