MIL-PRF-1/1065G

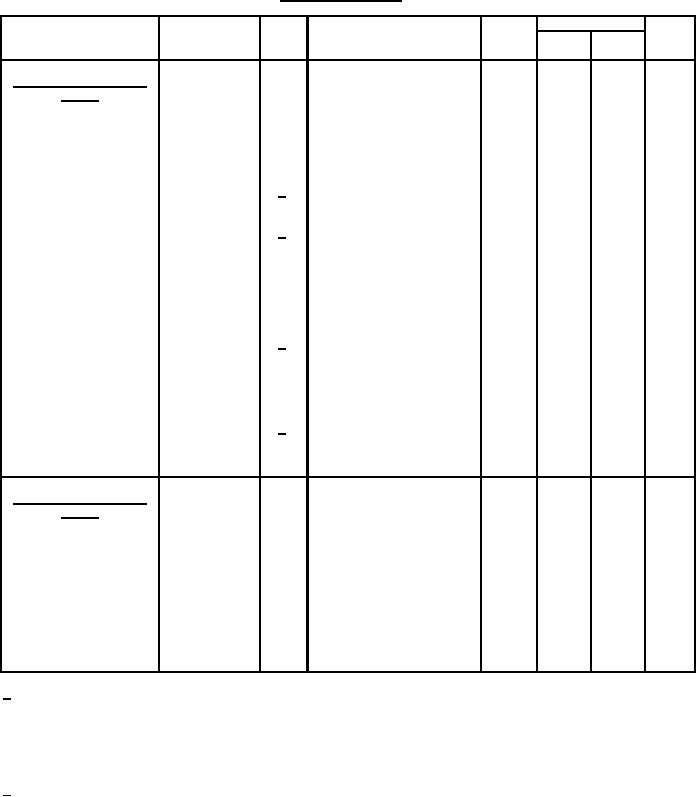

TABLE I. Testing and inspection - Continued.

Limits

Inspection

Method

Notes

Conditions

Symbol

Min

Max

Unit

MIL-STD-1311

Conformance inspection,

part 2

Heater current

1301

---

If

270

330

mA

Halfway between pins No. 1

---

---

---

---

Side terminal and base

5101

---

and No. 9

alignment

5/

---

---

---

---

5101

Neck and bulb alignment

(magnetic types)

5/

---

---

---

---

Face tilt

5101

5216

---

Eb1 = 11,000 V dc

---

---

---

---

Stray light emission

(conventional types)

Screen (P7 type)

5221

---

Eb1 = 5,000 V dc;

---

---

---

---

Ib1 = 48 A dc

Ib = 200 A dc

6/

Width

---

0.33

mm

Line width A

5226

(magnetic deflection)

A dc

15

---

Ihk

5251

---

Ehk = +180 V dc

Heater cathode leakage

A dc

15

---

Ihk

Ehk = -180 V dc

current

7/

Ratio

---

1.20

---

Astigmatism

---

Permanence of marking

1105

---

---

---

---

---

Conformance inspection,

part 3

Life test

---

---

Group C;

---

---

---

---

Eb1 = 11,000 V dc;

Ib = 60 A dc;

t = 500 hours

Life-test end points:

---

200 A dc;

Line width A

5226

---

Width

---

0.33

mm

Ec1

200 A dc

Modulation

5223

---

---

34

V dc

1/ The following information and materiel shall be made available to the Government representative conducting the qualification

inspection measurements with four regular qualification samples:

(a) The gun drawing with significant dimensions.

(b) A sample of the gun to be used in manufacturing of the tubes.

2/ Maximum rated voltages are applied to all electrodes connected through the base, and with tube in cutoff conditions.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business