MIL-PRF-1/952H

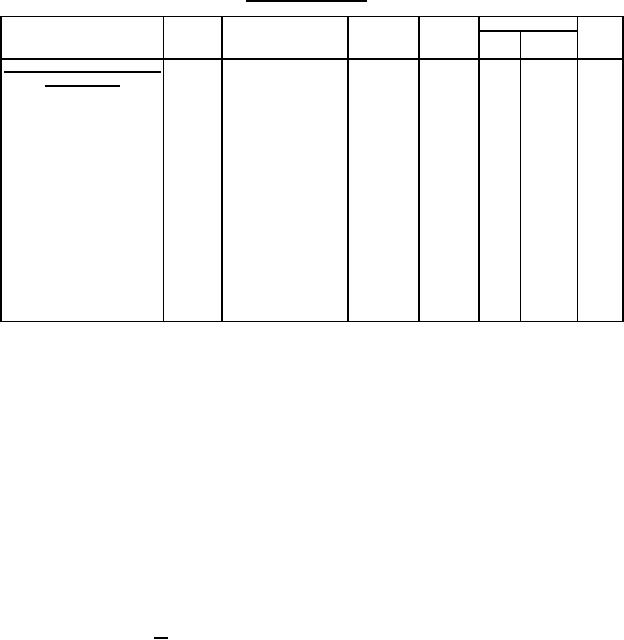

TABLE I. Testing and Inspection - Continued

Acceptance

Limits

Requirement or Test

Method

Conditions

Symbol

Unit

level

Min

Max

note 9

Conformance inspection, part

3 Continued

Total grid current

1266

---

Ic1

0

-1.0

uA dc

Heater current

1301

---

If

275

333

mA

Change in transcon-

1306

---

%Sm

---

25

%

ductance (1) of

t

individual tubes

%Sm

Transconductance (2)

1306

---

---

20

%

Ef

Heater-cathode leakage

---

Ihk

---

20

uA dc

MegΩ

Insulation of electrodes

---

R

50

---

Ef = 6.9 V

Cathode interface life

1511

---

Ri

---

50

ohms

See note 10

NOTES:

1.

See "Reduced pressure (altitude) rating" and altitude, maximum peak voltage.

2.

Tie grid 3 co negative terminal of cathode resistor.

3.

This test shall be performed at the conclusion of the holding period.

4.

Prior to this test, tubes shall be preheated for a minimum of 5 minutes at the conditions indicated below. The 3-minute

test shall not be permitted. Test at specified conditions within 3 seconds after preheating. Grid emission shall be the last

test performed on the sample selected for the grid-emission test.

Ef

Ec1

Ec2

Ec3

Eb

Rh

Rg1

MegΩ

V

V dc

V dc

V dc

V dc

Ohms

7.5

0

150

0

300

80

0.5

A grid resistor of 0.1 MegΩ shall be added; however, this resistor shall not be used when a thyatron-type short indicator is

5.

employed.

6.

This test shall be performed yearly. An accept on zero defect sampling plan be used with sample of three tubes with an

acceptance number of zero. In the event of failure, the test will be made as a part of conformance inspection, part 2,

acceptance level 6.5 (see 10/). The yearly sampling plan may be reinstated after three consecutive samples have been

accepted.

7.

Acceptance sampling procedure shall be in accordance with "base-strain test, miniature sampling" (method 1121), except

that data covered in "Acceptance and rejection criteria" shall be modified as follows:

(a)

Accepted if no defectives for class `A', `B', or `C' defects, respectively (see method 1121), or if no defectives are

found in the sample.

(b)

Rejected if any defectives for class `A', `B', or `C'defects, respectively, or if any defectives are found in the sample..

8.

Envelope temperature (TE) requirements, when measured in accordance with the temperature by conduction-band

measurement (method 1226), will be satisfied if a tube having bogey Ib (±5 percent) under normal test conditions, is

determined to operate at or above minimum specified temperature at any position in the life-test rack.

9.

This specification sheet utilizes an accept on zero defect sampling plan in accordance with MIL-PRF-1, table III.

10. The life-test sample shall consist of the lesser of 20 tubes or 10% of lot size and no failures shall be permitted. In the

event of failure of the first sample, a second sample of the lesser of 20 tubes or 10% of lot size shall be selected from the

lot. Acceptance shall then be based on the second samples, and no failures shall be permitted.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business