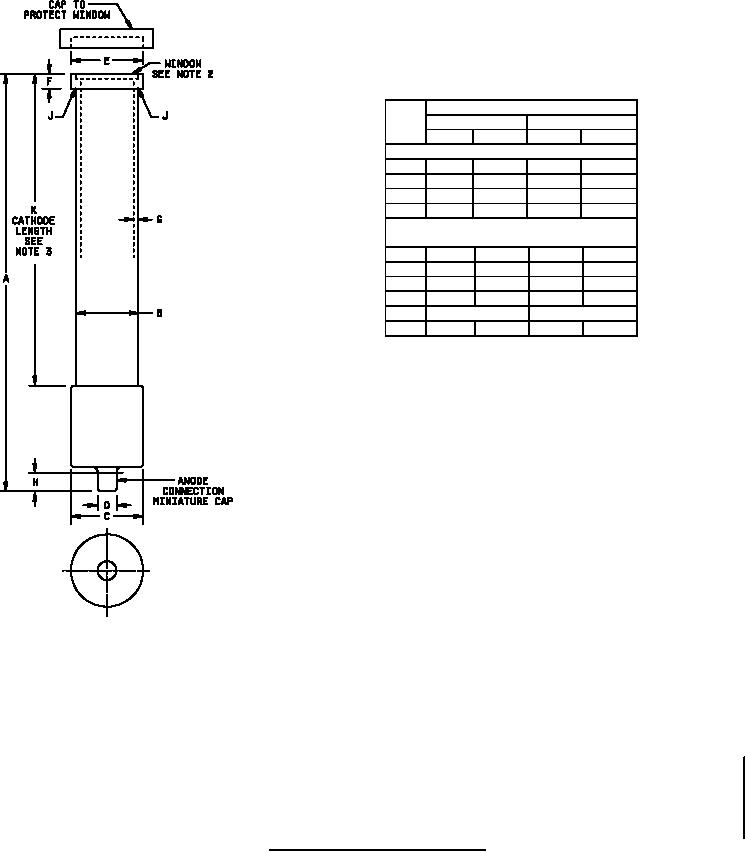

MIL-PRF-1/906E

Dimensions

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 2

A

5.750

6.000

146.05

152.40

B

.860

.890

21.84

22.61

C

---

1.000

---

25.40

E

.985

1.015

25.02

25.78

Conformance inspection, part 3

(see note 4)

D

.245

.255

6.22

6.48

F

.150

.225

3.81

5.72

G

.047

.078

1.19

1.98

H

.250

---

6.35

---

J

89°

91°

K

4.250

4.500

107.95

114.30

NOTES:

1. The envelope will not have an exposed seal-off tip.

2

2.

Mica window 3.0 to 4.0 milligrams per cm .

3.

Cathode: Allegheny Ludlum Sealmet 1 Steel for glass to metal seals, or equal.

4.

Dimensions shall be checked during the initial production and once each succeeding 12-calendar months in which there is

production. An accept on zero defect sampling plan shall be used, with sample of three tubes with an acceptance number of

zero defects. In the event of failure, the test will be made as a part of conformance inspection, part 2, with an acceptance

level of 6.5. This specification sheet uses an accept on zero sampling in accordance with MIL-PRF-1, table III. The regular

"12-calendar month" sampling plan shall be reinstated after three consecutive samples have been accepted.

FIGURE 1. Outline drawing of electron tube type 5979.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business